TM-9-2330-326-14-P - Page 55 of 540

TM 9-2330-326-14&P

3-7

Table 3-1. Operator/Crew PMCS (Cont.)

ITEM

NO.

INTERVAL

ITEM TO CHECK/

SERVICE

PROCEDURE

EQUIPMENT NOT

READY/AVAILABLE IF:

CAUTION

•

Rust near wheel nuts can mean

low torque.

•

Check wheels (inner/outer) and

hubcaps

for

grease

leakage.

When leakage is initially found,

clean off all grease and recheck

after operation. If grease leakage

is

still

evident,

notify

Unit

maintenance.

NOTE

•

All

wheel

flange

nuts

have

right hand threads.

•

Cold radial tire pressure

should be 115 psi (793 kPa) for

all tires.

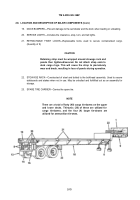

11

Before

Radial Tires and

Wheels

a.

Inspect

tires,

including

spare,

for

proper inflation, unusual tread wear,

sidewall

damage,

cuts,

foreign

objects, valve stem damage, valve

caps, and loose/missing dust shield

plugs on wheels.

WARNING

Make sure spare tire is secured in

carrier and securing hardware is

present

.

Failure to secure these

properly can result in injury or

death to personnel.

Tires are not properly

inflated, damaged, or show

unusual wear.

Securing hardware is

unserviceable or missing.

b.

Check wheels for damaged rims,

rust, or leaking grease.

c.

Check for loose or missing wheel

nuts. Notify Unit maintenance. All

the

nuts

must

be

present

and

torqued to specifications.

Re-torque wheel nuts at first 100, 500,

1000 miles (161, 805, 1609 km), and

every 6000 miles (9656 km) thereafter

unless wheel is changed out. Then use

re-torque

schedule.

Notify

Unit

maintenance. (See Appendix H-22.)

Wheel rims are damaged,

rusty, or shows signs of

leaking grease.

Nuts are loose or missing.

Wheel nuts not torqued.

Back to Top