TM-9-2330-342-23-P - Page 369 of 1348

FIELD MAINTENANCE

SERVICE BRAKE(S) ON ONE AXLE DO NOT APPLY OR APPLY SLOWLY

INITIAL SETUP:

Tools and Special Tools

MSD/ICE, Test Set, Electronic Systems

(WP

0194, Table 1, Item 27)

MSD-V2, Test Set, Electronic Systems

(WP

0194, Table 1, Item 28)

Tool Kit, General Mechanic’s: Automotive

(WP

0194, Table 1, Item 47)

Materials/Parts

Solution, Soap (WP

0193, Table 1, Item 58)

Pin, Cotter (WP

0195, Table 1, Item 75)

Pin, Cotter (WP

0195, Table 1, Item 16)

Personnel Required

Wheeled Vehicle Mechanic (2)

References

WP

0004

References (cont.)

WP

0066

WP

0067

WP

0071

WP

0072

WP

0076

WP

0078

WP

0086

WP

0092

Equipment Condition

Parking brake applied (TM 9-2330-342-10).

(WP

0190)

Wheels chocked (TM 9-2330-342-10). (WP

0190)

Emergency air supply gladhand connected to

vehicle (TM 9-2330-342-10). (WP

0190)

Trailer air system charged (TM 9-2330-342-10).

(WP

0190)

TROUBLESHOOTING PROCEDURE

SERVICE BRAKE(S) ON ONE AXLE DO NOT APPLY OR APPLY SLOWLY

STEP 1

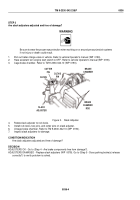

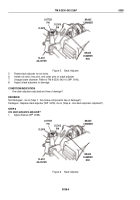

Are air lines, fittings, relay valve, and brake chamber(s) free of leaks and/or crimps?

NOTE

•

Soap and water solution will be used to visually check for leaks.

•

Trailer air system pressure must be 125 ± 5 psi (861 ± 34 kPa) to begin

troubleshooting the brake system. If the air system pressure cannot be maintained,

refer to Air System Troubleshooting.

•

Air lines and valves listed in this troubleshooting procedure are illustrated and located

in Air System Schematic.

1.

Inspect air lines listed in table and fittings for crimps.

TM 9-2330-342-23&P

0038

0038-1

Back to Top