TM-9-2350-238-20-1 - Page 881 of 1364

TM 9-2350-238-20-1

23

24

25

26

27

28

Install ten new self-locking nuts (20).

Tighten ten self-locking nuts (20) to 200 to 220 ft-lb (271 to 298 N-m) (lubricated) or 270 to 300

ft-lb (366 to 407 N-m) (dry).

Raise spade (21) until roadwheels 2 thru 4 and idler wheel are on ground. For number 1

roadwheel, lower jack until wheel is on ground. Remove jack.

Remove two 8 x 8 x 12-in. (20 x 20 x 31-cm) wood blocks from behind vehicle.

Release parking brake.

Drive vehicle forward until idler wheel or roadwheel is on track (22).

This task covers:

a.

Removal/Disassembly

c.

Reassembly/Installation

b.

Inspection/Repair

INITIAL SETUP

Tools and Special Tools

Materials/Parts

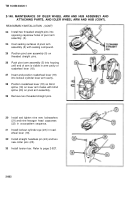

Automotive maintenance and repair shop

Arm bearing seal idler wheel sleeve

equipment: organizational maintenance,

Cotter pin (4)

common no. 1 (less power) (item 80,

Grease (item 20, appx C)

appx B)

Inner bearing ring (2)

●

Bar

Inner bearing ring (2)

●

Puller

Lockwasher (18)

●

Torque wrench (0 to 600 ft-lb)

Plain encased seal (2)

Bearing inserter (item 10, appx G)

Plain encased seal (2)

Hexagon head capscrew (3) (item 22,

Plain encased seal (2)

appx G)

Plain encased seal (2)

Idler adjustment wedge (item 29, appx G)

Preformed packing (2)

Manual control handle (item 8, appx G)

Roller bearing (2)

Puller adapter (item 2, appx G)

Roller bearing (2)

Race and outer bearing replacer (item 20,

Sealing compound (item 39, appx C)

appx G)

Self-locking nut (4)

Remover and replacer handle (item 9,

Wiping rag (item 33, appx C)

appx G)

Seal inserter (item 12, appx G)

Personnel Required

Seal inserter (item 13, appx G)

Two

Slide puller (item 18, appx G)

Sling (item 82, appx B)

References

Spanner wrench (item 33, appx G)

TM 9-2350-238-10

Threaded straight pin (2) (item 17, appx G)

TM 9-2350-238-24P-1

Torque wench extension (item 5, appx G)

Equipment Conditions

2-864 Idler hub removed

2-148. MAINTENANCE OF IDLER WHEEL ARM AND HUB ASSEMBLY AND

ATTACHING PARTS, AND IDLER WHEEL ARM AND HUB.

2-855

Back to Top