TM-9-2350-256-10 - Page 594 of 796

Table 1.

Operator Preventive Maintenance Checks and Services (PMCS) – Monthly - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

19

MONTHLY

Compensating

Idler Wheels and

Arms

CAUTION

Do not lubricate compensating idler wheels

using air pressure exceeding 15 psi

(103 kPa). Failure to comply may result in

blown seals and damage to equipment.

NOTE

Perform Steps 1 and 2 for mechanic and

operator side of vehicle.

1. Lubricate compensating idler wheel bearings

through fittings until relief valve opens (WP 0101).

2. Lubricate idler arm bearings through fittings until

grease is visible (WP 0101).

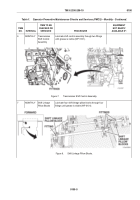

Figure 20.

Compensating Idler Wheels and Arms.

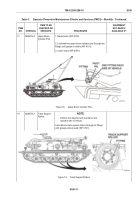

20

MONTHLY

Roadwheel Hub

Bearings and

Pivot Arm

Assembly

CAUTION

Do not lubricate roadwheel hub bearings

using air pressure exceeding 15 psi

(103 kPa). Failure to comply may result in

blown seals and damage to equipment.

1. Lubricate roadwheel hub bearings through 12 fittings

(one on each roadwheel hub) until safety relief valve

opens (WP 0101).

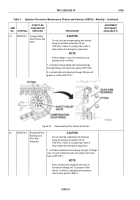

NOTE

Some vehicles are equipped with only 24

lubrications fittings and 12 pressure relief

valves. If vehicle is equipped with pressure

relief valves, perform Step 3.

TM 9-2350-256-10

0100

0100-12

Back to Top