TM-9-2350-311-10 - Page 151 of 775

TM 9--2350--311--10

Change 6

2--59/(2--60 blank)

Table 2--1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR M109 SELF-PROPELLED HOWITZER — CONTINUED

Location

Item

No.

Not Fully Mission

Capable If:

Crewmember

Procedure

Item to Check/

Service

Interval

39

After

Bore

Evacuator

CHIEF OF SECTION

NOTE

•

Some rotation of the bore evacuator is

acceptable. However, if it rotates more than 1

inch (2.54 cm), check to ensure setscrew

locks bearing ball. Notify unit maintenance if

problem persists.

•

Do not fill metering holes with grease. Filling of

the holes will decrease efficiency of the bore

evacuator.

Clean evacuation orifices and ensure that bottom

setscrew (not shown) is staked.

Staked setscrew,

ball or spring is

missing.

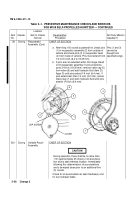

Inspect valve ring (1) for cracks or deformation.

Valve ring (1) is

broken.

Clean cannon tube (2) threads.

NOTE

Notify unit maintenance if valve ring is cracked or

deformed, or if threads are burred or damaged.

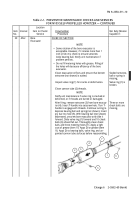

After firing, remove setscrew (3) from bore evacua-

tor (4). Insert T-handle into setscrew hole. Turn T-

handle to engage with threads. Continue turning to

depress bearing ball and spring (not shown). Insert

pry bar into hole (5). With bearing ball (not shown)

depressed, unscrew bore evacuator and slide it

forward. Slide valve ring (1) forward and 10 check

balls (6) should fall out. Thoroughly clean check

balls and three metering holes (7). Apply a light

coat of grease (item 19, Appx D) or grease (item

18, Appx D) to bearing balls, valve ring, and un-

painted cannon tube surfaces before reassembling.

Three or more

check balls are

missing.

4

2

5

3

1

6

7

Back to Top