TM-9-2350-311-20-1 - Page 946 of 1275

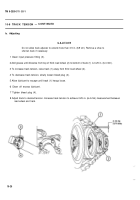

7 Torque nut (9) as follows:

(a) Using torque wrench, tighten nut to 100 Ib-ft (136 N·m).

(b) Back off nut 1 complete turn.

(c) Using torque wrench, tighten nut to 25-30 Ib-ft (34-41 N·m) while rotating hub (4).

(d) If slots in nut and hole in spindle aline, install new cotter pin (8).

(e) If slots in nut and hole in spindle are misalined, back off nut to aline with first hole in

spindle, and install new cotter pin (8). Range of back-off is 0 to 30°.

(f) After adjustment, hub (4) must rotate freely by hand.

8 Install new preformed packing (11), static spring (7), and cap (2). Install six washers (6) and six cap screws (5).

Tighten screws to 12 Ib-ft (16 N·m).

9 Install grease fitting (1) and relief valve (3).

10 Fill hub (18) with grease until air-free grease flows from relief valve.

FOLLOW-ON MAINTENANCE:

NOTE

Install road wheels (para 10-10)

10-29

TM 9-2350-311-20-1

Back to Top