TM-9-2350-311-20-1 - Page 949 of 1275

10-13 TORSION BARS — CONTINUED

b. Installation

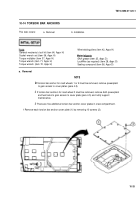

1 See torsion bar ID chart information applicable to torsion bar (4) you are replacing (para 10-9).

2 Lubricate splines at end of torsion bar (4) with grease.

3 Clean and

CAUTIO N

Do not remove protective tape from ground (unsplined) surface of torsion bars.

Do not use any tool other than torsion bar slide hammer puller.

Torsion bar should slide in by hand. If not, use slide hammer puller as necessary.

dry torsion bar (4) anchor cavities (para 10-14).

NOTE

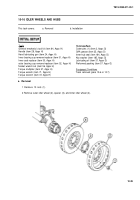

Hold road wheel arms 1 thru 6 at 4 o’clock position on vehicle left side and 8 o’clock

on right; hold number 7 road wheel arm at 8 o’clock on vehicle left side and 4 o’clock

on right side while installing torsion bars.

4 Insert torsion bar (4) making certain splines on each end of torsion bar are alined with blind splines in anchor

and road wheel arm (5).

5 Torque torsion bar anchor screws and install Iockwire (para 10-14).

6 Install new gasket (3) and torsion bar plug (2).

7 Install screw (1). Torque screw to 90 Ib-ft (122 N·m).

NOTE

FOLLOW-ON MAINTENANCE:

Install road wheels (para 10-10)

10-32

TM 9-2350-311-20-1

Back to Top