TM-9-2350-311-20-2 - Page 416 of 828

TM 9–2350–311–20–2

7–10.2

Change 2

7–2

RAMMER ASSEMBLY — CONTINUED

d.

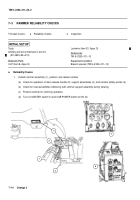

Assembly — Continued

7

Install rammer handle (50.3), four flat washers (50.2), and four cap screws (50.1).

8

Apply sealing compound to threads of hex nut (45) and shoulder bolt (46). Install helical torsion spring (49),

lock-release lever (48), flat washer (47), shoulder bolt (46), and hex nut (45) to front cylinder support (50).

Torque bolt to 34–42 lb–ft (46–57 N

.

m).

9

Install mounting bracket (44) and two cap screws (43) to tray (24).

10

Apply sealing compound to threads of seven cap screws (40). Install tray (24), rammer latch (42), two cap

screws (41), and seven cap screws (40). Torque cap screws (40) to 32–39 lb–ft (43–53 N

.

m).

11

Install angle bracket (21), flat washer (38), helical compression spring (37), flat washer (36), two hex nuts

(35), and two rod end bearings (18) to rod (39).

12

Install rod group (34).

13

Install lever (33), straight headed pin (32), flat washer (31), and new cotter pin (30) on mounting bracket

(29).

NOTE

If straight headless pin (27) is new from supply, perform step 14.

14

Drill 3 holes in straight headless pin (27) using handle (28) and lever (33) for pilot holes. Spring pins (26)

inserted through handle (28) require a 1/8 inch (3.2 mm) hole. Spring pins (25) inserted through lever (33)

require a 5/32 inch (3.7 mm) hole.

15

Install handle (28), straight headless pin (27), two new spring pins (26), and spring pins (25) on mounting

bracket (29).

16

Install handle group (23) and four cap screws (22) on tray (24).

17

Install two flat washers (20) and two cap screws (19) on angle bracket (21).

18

Insert straight headed pin (17) into one rod end bearing (18).

19

Install flat washer (16) and new cotter pin (15) on straight headed pin (17).

20

Install adapter (14.2) and adapter (14.1) on rear cylinder support (14.3).

21

Install metallic tube (13.1), elbow (13) on cylinder assembly (14).

Back to Top