TM-9-2350-311-20-2 - Page 422 of 828

TM 9–2350–311–20–2

7–16

Change 3

7–3

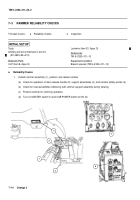

RAMMER RELIABILITY CHECKS — CONTINUED

b.

Inspection

CAUTION

•

Do not paint plunger or bridge clamp on rammer valve as it could cause damage to equipment.

Lubricate per TM 9–2350–311–10.

•

Make sure that rammer actuating lever is in inactive (out) position before placing rammer as-

sembly in upright position to avoid damage to equipment.

1

Set the rammer in ram position.

2

Visually check alinement of plunger (10) with bridge clamp (11). If plunger is disengaged remove and dis-

card lockwire (11.1), loosen two cap screws (12). Slide angle bracket (13) in direction required to engage

with plunger. Tighten two cap screws (12) and torque to 35 to 45 ft-lbs. Secure two cap screws (12) with

new lockwire (11.1).

3

Check operation of rammer (para 7–3a.).

BLOCKING VALVE

12

13

12

DO NOT PAINT

11

10

11.1

Back to Top