TM-9-2350-311-34-1 - Page 98 of 352

WARNING

TM 9-2350-311-34-1

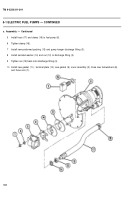

5-2 FUEL TANKS — CONTINUED

b. Repair — Continued

13

14

15

16

17

18

19

20

Remove release film.

Repeat this procedure for application of second patch.

Saturate remaining patches with mixture without silica and apply to crater.

Allow completed patch to set undisturbed for 16 to 24 hours.

NOTE

Cure will be slow in temperatures below 70°F (21°C). However, during first hour of

cure, temperature should not exceed 100°F (38°C).

To cure in about 4 hours, after patch has cured for 1 hour, place heat lamp over patch and gradually increase

intensity. Keep lamp at least 2 ft (0.6 m) from patch and do not allow temperature to exceed 250°F (121°C).

• Naphtha is flammable. Do not smoke or allow open flames in areas where naphtha

is being used to avoid possible explosion or injury.

●

Chemical Agent Resistant Coating (CARC) paint contains isocyanate, a

constituent that can cause respiratory effects during and after the application of the

material. CARC paint may produce itching and reddening of the skin, a burning

sensation of the throat and nose, and watering of the eyes. Refer to TM 9-2350-

311-20-1 for complete CARC handling instructions.

When cure is complete, sand patch flush with surrounding surface. Clean with naphtha and paint fuel tanks

(TM 9-2350-31 1-20-1).

Compressed air used for cleaning purposes must not exceed 30 psi (207 kPa). Use

only with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc).

Pressure test repaired tank using low-pressure compressed air at 3 psi (21 kPa).

Thoroughly flush tank and dry with low-pressure compressed air.

NOTE

Steps 21 thru 25 apply to tanks with holes 1 in. (25.4 mm) across at any point.

5-16

Back to Top