TM-9-2520-254-34 - Page 10 of 126

CHAPTER 2

DESCRIPTION AND OPERATION

Section I. DESCRIPTION AND OPERATION OF TRANSMISSION COMPONENTS

2-1. Torque Converter and Lockup Clutch

a. Torque Converter Components

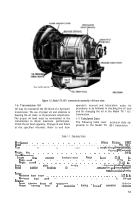

(fig. 2-1).

(1) The torque converter consists mainly of

three cast aluminum elements: a converter pump

(8), converter turbine (6), and a stator and cam

assembly (7). In addition, there are other parts in

the group which house and support these main

elements.

(2) The converter pump assembly (8) is the

driving element. It rotates on a ball bearing

assembly (9) supported by a converter ground

sleeve (10) which is stationary and a component of

the diaphragm assembly (12). The pump is bolted

to a cover assembly (4) which rotates with the

engine crankshaft.

(3) The converter turbine assembly (6)

is the

driven element. It is splined to a turbine shaft (59)

which transmits torque to a high-range clutch

housing (16), intermediate-range sun gear (53),

and a low-range sun gear (46). The turbine hub (2)

is splined to a lockup clutch plate (5).

(4) The stator and cam assembly (7) is the

reaction element. It is mounted on an over-running

clutch on a freewheel roller race (63) which is

splined to a ground sleeve (10). The stator is free to

rotate in the direction of engine rotation but locks

up in the opposite direction.

b. lockup Clutch Components

(fig. 2-1).

(1) The lockup clutch piston assembly (64) is

a spring steel diaphragm with a clutch apply plate

at its outer circumference. It is mounted on the

inner hub of the converter pump cover assembly

(4). and retained by a snap ring. Recesses in the

piston engage the heads of the converter drive bolts,

and prevent rotation of the piston relative to the

pump cover.

(2) The lockup clutch plate (5) is a non-

metallic, internal-splined plate. It is splined to the

converter turbine hub and located between the

piston (64) and the lockup clutch back plate (62).

(3) The lockup clutch back plate (62) is a

pressed steel ring against which the plate (5) reacts

when the lockup clutch is applied. Its outer

diameter is held between the converter pump cover

(4) and tbe pump (8) which are bolted together.

c. operation of Torque Converter and Lockup

Clutch

(fig. 2-1).

(1) The actions of the torque converter and

lockup clutch are interrelated. When the lockup

clutch is released, the torque converter must

transmit engine power to the transmission. When

the lockup clutch is engaged, there is no converter

action and torque is transmitted directly from

engine to transmission because the input drive

components and converter turbine (6) are locked

together.

(2) When the lockup clutch is released, the

torque converter (which is constantly filled with oil)

transmits torque by hydraulic action. The blades of

the pump (8) throw oil against the blades of the

turbine (6), causing the turbine to rotate in the

same direction as the pump. Higher pump speeds

cause the oil to be thrown with more force, causing

a greater rotating force in the turbine. At engine

idle speed, the force of the oil, and consequently the

torque transmitted, is negligible. This characteristic

of hydraulic drive permits the torque converter to

take the place of a friction clutch between the

engine and transmission.

(3) The turbine vanes direct the oil toward the

center of the turbine (6), where the oil leaves the

turbine in a direction opposite to pump rotation.

The stator (7) redirects the flow of oil to change its

direction to that of pump rotation. Unexpended

energy in the oil reentering the pump (8) assists the

pump. This is the key to torque multiplication.

(4) Thus, the torque converter is a torque

multiplier as well as a fluid coupling. Torque

multiplication is highest when the turbine (6) is

stalled and the pump (8) is rotating at full speed. It

is lowest when the pump is rotating at its lowest

speed relative to the turbine.

(5) The oil, leaving the inner ends of the

turbine vanes, strikes the curved vanes of the stator

and is deflected into the pump vanes. It is the

reaction of the oil, as it is forced to change direc-

tion, which locks the stator against rotation op-

posite to pump and turbine rotation. When turbine

speed approaches pump speed, the oil leaving the

turbine strikes the back sides of the turbine vanes

and causes the stator to freewheel on the rollers

(61).

(6) When torque multiplication is no longer

required to provide sufficient power to the vehicle

drive line and vehicle speed is great enough, the

lockup clutch automatically engages. In lockup

operation there is no hydraulic slippage. The result

is economy

in operation and improvement in

operating characteristics.

2-1

Back to Top