TM-9-2815-205-24 - Page 475 of 856

FIELD MAINTENANCE

IDLER PULLEY ASSEMBLY REPAIR

INITIAL SETUP:

Tools and Special Tools

Tool Kit, General Mechanic's

(WP 0104, Table 1, Item 113)

Materials/Parts

Cleaning Solvent (WP 0103, Table 1, Item 8)

Equipment Condition

Idler pulley assembly removed (WP 0013)

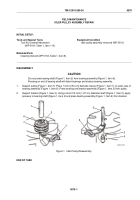

DISASSEMBLY

CAUTION

Do not press bearing shaft (Figure 1, Item 2) from bearing assembly (Figure 1, Item 6).

Pressing on end of bearing shaft will distort bearings and destroy bearing assembly.

1.

Support pulley (Figure 1, Item 7). Place 1 inch (2.54 cm) diameter sleeve (Figure 1, Item 1) on outer race of

bearing assembly (Figure 1, Item 6). Press bearing and bracket assembly (Figure 1, Item 3) from pulley.

2.

Support bracket (Figure 1, Item 4). Using a short 1/2 inch (1.27 cm) diameter shaft (Figure 1, Item 5), apply

pressure to bearing shaft (Figure 1, Item 2) and press bearing assembly (Figure 1, Item 6) from bracket.

7

1

5

2

6

2

3

4

6

MAINT_209

Figure 1.

Idler Pulley Disassembly.

END OF TASK

TM 9-2815-205-24

0076

0076-1

Back to Top