TM-9-2815-205-34 - Page 316 of 596

TM 9-2815-205-34

3-50. PISTON AND CONNECTING ROD MAINTENANCE - TRUNK (MODELS 5063-5299,

5063-5395, AND 5063-5398) (Cont)

NOT E

•

Thickness gages must be

perfectly flat and free of nicks

and bends.

•

Select a thickness gage thick-

ness requiring six pounds pull

to move. Piston to liner clear-

ance is 0.001 inch greater than

thickness of thickness gage

used. For example, a 0.004

inch thickness gage indicates

0.005 inch clearance when

withdrawn with a six pound

pull.

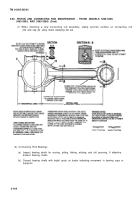

(2)

(3)

With cylinder liner (2) in cylinder block,

hold piston (13) upside down in liner and

measure clearance in four places, 90

degrees apart, using a thickness gage

(20) attached to a spring scale (21).

CIearance for model 5063-5299 must be

0.0027 to 0.0068 inch for new parts and

to 0.010 inch for used parts. Clearance

for models 5063-5395 and 5063-5398

must be 0.0047 to 0.0088 inch for new

parts and to 0.012 inch for used parts.

If binding occurs between piston and

liner, remove piston and examine piston

and liner for burrs. Remove burrs on

piston with an X-fine sharpening stone.

Remove burrs in liner with fine flat hone

and recheck clearance.

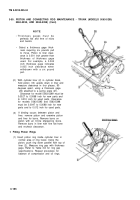

f. Fitting Piston Rings

(1) Insert piston ring inside cylinder liner in

normal area of ring travel. Using the

piston, push ring down parallel with top of

liner (2). Measure ring gap with thickness

gage. Refer to Table 3-6 for ring gap

specifications. Repeat procedure for

balance of compression and oil rings.

3-186

Back to Top