TM-9-2815-205-34 - Page 322 of 596

TM 9-2815-205-34

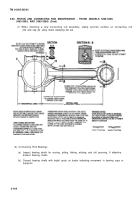

3-50. PISTON AND CONNECTING ROD MAINTENANCE - TRUNK (MODELS 5063-5299,

5063-5395, AND 5063-5398) (Cont)

(d) Place cylinder liner (2) with flange end

down on wood block.

NOT E

Numbers on side of connecting

rod and cap identify the

cylinder Iocation where they

were originally used.

(e) Place ring compressor (24) and piston

and connecting rod assembly (8) on

liner (2) with numbers on side of

connecting rod and cap aligned with

matchmark on liner (Para 3-52).

CAUTION

Do not force piston into liner.

Expanders apply considerable

force on oil rings; therefore,

exercise care during loading

operation to prevent ring

breakage.

(f)

(g)

Push piston and connecting rod

assembly (8) down into liner until

piston is free of ring compressor (24).

Remove connecting rod cap and then remove ring compressor from piston, connecting rod,

and liner assembly. Push piston down until compression rings pass cylinder liner ports.

(4) Repeat steps (1) thru (3) for remaining piston and connecting rod assemblies.

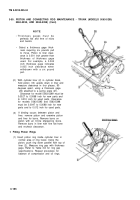

h. Installation - Cylinder Kit Assembly

CAUTIO N

Cylinder block bore grooves must be clean. Debris in grooves will cause coolant

leakage into engine oil and engine damage can result.

NOT E

If any pistons and liners are already in engine, use hold-down clamps (1) to retain liners

(2) in place when rotating crankshaft.

(1) Install two preformed packings (25) in cylinder block bore grooves.

3-192

Back to Top