TM-9-2815-205-34 - Page 326 of 596

TM 9-2815-205-34

3-51. PISTON AND CONNECTING ROD MAINTENANCE - CROSS-HEAD (MODELS 5063-5392,

5063-5393, 5063-539F, AND 5063-539L)

This task covers: a. Removal

b. Disassembly

c. Cleaning

d. Inspection

e. Fitting Piston

f. Fitting Piston Rings g. Assembly

h. Installation

INITIAL SETUP

MODELS

MATERIALS/PARTS

5063-5392 5063-5393 5063-539F

TOOLS AND SPECIAL TOOLS

1

1

Tool kit, general mechanics (App B, Item 107)

Wrench, torque (App B, Item 116)

Pliers, piston ring (App B, Item 75 )

Reamer, cylinder ridge (App B, Item 82)

Cleaner, piston ring groove (App B, Item 15)

Die set, metal stamping, hand (App B, Item 20)

Ball attachment, micrometer (App B, Item 8)

Installer, piston pin retainer (App B, Item 66)

Leak detector, piston pin retainer (App B, Item

71 )

Compressor, piston ring (App B, Item 16)

Clamps, hold-down (App B, Item 14)

Gage set, piston-liner thickness (App B, Item 32 )

Spring scale

Gage set, thickness

Micrometer 0-1 inch App B, Item 73 )

Micrometer 0-1 inch

Micrometer 3-4 inch

Micrometer 1-2 inch

Vise, machinist (App B, Item 111 )

Caps, vise jaw (App B, Item 13)

2

Ring, piston (App F, Item 143)

1

Rings, piston (App F, Item 142)

Ring set, oil (App F, Item 138)

2

Retainers, piston pin (App F, Item

135)

Packings, preformed (App F, Item 116)

2

Bolts (App F, Item 10)

2

Spacer (App F, Item 181)

1

Seal, ring (App F, Item 175)

EXPENDABLE/DURABLE SUPPLIES

Carbon removing compound (App C, Item 5)

Cleaning solvent (App C, Item 9)

Plastic gage, green (App C, Item 16)

C

Plastic gage, red (App , Item

Stone, sharpening (App

Oil, engine (App C, Item 26)

Wood block (App C, Item 58)

Crocus cloth (App C, Item 10)

Oil, fuel (App C, Item 27)

Shortening compound (App C,

Antifreeze (App C, Item 3)

EQUIPMENT CONDITION

17) ‘

C, Item 51)

Item 47)

Para Description

3-33 Oil pan removed

3-35 Oil pump inlet tubes removed

3-43 Cylinder head removed

a. Removal

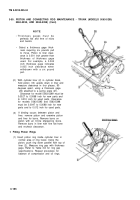

(1) Install hold-down clamps (1) to each cylinder to anchor liners (2) during crankshaft rotation.

(2) Rotate crankshaft (3) until connecting rod journal (4) is at bottom of its travel.

(3) Remove hold-down clamp (1) from cylinder being worked on.

CAUTION

Remove all carbon deposits at top of liner before removing piston from cylinder liner.

Piston ring breakage can occur when carbon deposits are present.

(4) Using a cylinder ridge reamer, remove carbon deposits from upper inner surfaces of cylinder

liner (2).

3-196

Change 1

Back to Top