TM-9-2815-213-34 - Page 7 of 192

*TM 9-2815-213-34

LIST OF ILLUSTRATIONS

Number

Title

Page

Number

Title

Page

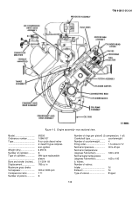

1-1.

Model V8-300 .

.....

Engine Assembly

3/4 Left

3-12.

Piston Ring Gap Check.

....................................

3-7

Front View .

................................................

1-2

3-13.

Rod Side Clearance Check .

..............................

3-8

1-2.

Model V8-300 Engine Assembly 3/4

Right .

..

3-14.

Crankshaft Oil Seal-Removal/Installation.

.........

3-9

Rear View

................................................

1-3

3-15.

Front Cover Bore Alinement Check .

.................

3-9

1-3.

Engine Assembly Rear Sectional View .

........

1-6

3-16.

Front Cover to Block Alinement Check .

............

3-9

2-1.

Exhaust Manifold-Removal/Installation .

........

2-4

3-17.

Drive Gear Backlash Check .

............................

3-10

2-2.

Oil Cooler-Removal Installation .

....................

2-5

3-18.

Camshaft End Play Check .

..............................

3-11

2-3.

Engine Rebuild Stand-Removal

/ ...................

3-19.

Crankshaft Gear Backlash Check .

....................

3-11

Installation.

.................................................

2-5

3-20.

Crankshaft Adapter Tightening Sequence .

.......

3-12

2-4.

Fan Hub and Bracket Assembly-.

..................

3-21.

Flywheel Housing Concentricity Check

...........

3-13

Removal/Installation .

................................

2-5

3-22.

Flywheel Tightening Sequence .

........................

3-14

2-5.

Thermostat Assembly-Removal

/ ...................

3-23.

Flywheel Bearing Bore and Wobble Limits

3-14

Installation .

................................................

2-6

3-24.

Tappet Assembly Tes

t ......................................

3-15

2-6.

Drive Pulleys and Vibration Damper- .

...........

3-25.

Cylinder Head in Holding Fixture

.....................

3-16

Removal/Installation .

.................................

2-6

3-26.

Valve Assemblies-Removal/Installation .

...........

3-16

2-7.

Water Pump Assembly-Remova

l ..................

3-27.

Injector Sleeves-Removal/Installation .

.............

3-16

Installation .

................................................

2-6

3-28.

Crosshead Guide-Removal/Installation.

............

3-16

2-8.

Air Intake Crossover and Preheater .

.............

3-29.

Valve Seat Removal Sectional View .

................

3-17

Assembly-Removal/Installation.

.................

2-7

3-30.

Injector Sleeve Holder Installation .

...................

3-17

2-9.

Intake Manifold, Fuel Pump and Fuel .

...........

3-31.

Injector Tip Protrusion Measurement .

...............

3-17

Lines-Removal/Installation .

.......................

2-7

3-32.

Valve Head and Collet Check .

..........................

3-18

2-10.

Water Crossover Pipe and Lifting Eye .

.........

3-33.

Crosshead Guide Check

.................................

3-18

Removal/Installation .

................................

2-8

3-34.

Valve Guide Check .

..........................................

3-18

2-11.

Oil Dipstick Tube Assembly-Removal

/ ..........

3-35.

Valve Spring Test

............................................

3-18

Installation .

................................................

2-8

3-46.

Valve and Injector Counterbore Measure-

.

2-12.

Cylinder Head Covers-Removal/ .

..................

ments .

...............................................................

3-19

Installation.

.................................................

2-9

3-37.

Cylinder Head Regrooving .

...............................

3-19

2-13.

Crankcase Breather Tube Removal/ .

............

3-38.

Valve Guide Installation .

...................................

3-20

Installation.

.................................................

2-9

3-39.

Crosshead Guide Installation- .

..........................

3-20

2-14.

Push Rod Cavity Covers-Removal/ .

..............

3-40.

Injector Sleeve Installation .

..............................

3-20

Installation.

.................................................

2-9

3-41.

Injector Sleeve Rolling-Upper Portion .

..............

3-21

2-15.

Rocker Arms and Push Rods-Removal/.

.......

3-42.

Injector Sleeve Rolling-Lower Portion .

..............

3-21

Installation.

.................................................

2-10

3-43.

Injector Sleeve Seat Cutting.

.............................

3-21

2-16.

Injector Clamps Removal/Installation .

...........

2-10

3-44.

Valve Seat Insert Counterbore .

........................

3-21

2-17.

Fuel Injector and Hold-Down Clamp.

.............

2-10

3-45.

Intake Valve Port Swirl Plate Installation.

..........

3-22

2-18.

Valve Crossheads-Removal/Installation .

.......

2-11

3-46.

Valve Seat Insert Peering .

................................

3-22

2-19.

Cylinder Head-Removal/,Installation .

............

2-11

3-47.

Valve Seat Test.3.

.............................................

3-22

2-20.

Valve and Injector Tappets-Removal

/ ...........

3-48.

Cylinder Head Tightening Sequence .

...............

3-23

Installation.

.................................................

2-11

3-49.

Fuel Injector PT (Type C).

.................................

3-24

2-21.

Flywheel-Removal/Installation.

......................

2-12

3-50.

Injector Cup-Removal/Installation .

....................

3-24

2-22.

Crankshaft Adapter-Removal/Installation

2-12

3-51.

Injector Link-Removal/Installation .

....................

3-24

2-23.

Flywheel Housing-Removal/Installation.

........

2-13

3-52.

Plunger Seat Pattern .

.......................................

3-24

2-24.

Camshaft Gear, and Spacer Plate- .

..............

3-53.

Fuel Injector-Exploded View.

.............................

3-26

Removal/Installation .

.................................

2-13

3-54.

Injector Check Ball Seating .

..............................

3-26

2-25.

Oil Pan-Removal/Installation .

........................

2-13

3-55.

Injector Body 0-Ring Installation .

......................

3-26

2-26.

Oil Pump Assembly-Removal/Installation

2-13

3-56.

Injector Body and Plunger Markings .

................

3-27

2-27.

Front Cover-Removal/Installation .

.................

2-14

3-57.

Injector Cup Markings .

.....................................

3-27

2-28.

Connecting Rod and Piston Assembly- .

........

3-58.

Injector Plunger Seat Test.

................................

3-27

Removal/Installation .

.................................

2-14

3-59.

Injector Test Stand-.

..........................................

3-29

2-29.

Crankshaft and Main Bearings-Removal/.

.....

3-60.

Alining Timing Wheel and Pointer .

....................

3-29

Installation.

.................................................

2-14

3-61.

Hydraulic and Air Valves .

..................................

3-29

3-1.

Camshaft Bushing Removal .

........................

3-1

3-62.

Air Pressure Adjustmen

t ...................................

3-30

3-2.

Cylinder Sleeve Removal .

............................

3-1

3-63.

Master Injector Installation- .

..............................

3-30

3-3.

Main Bearing Bore Alinement Check.

............

3-2

3-64.

Fuel Inlet Installation .

........................................

3-30

3-4.

Cylinder Sleeve Seals Installation .

................

3-2

3-65.

Injector Mounted in Test Stand .

........................

3-30

3-5.

Crankshaft Dimensions .

................................

3-4

3-66.

Test Stand Air Pressure Connection .

................

3-31

3-6.

Crankshaft End Clearance Check .

................

3-5

3-67.

Load Cell Test .

..................................................

3-31

3-7.

Bearing Cap to Block Clearance Check .

.......

3-5

3-68.

Ball Seat Resurfacing.

.......................................

3-32

3-8.

Side Bolt Tightening Sequence .

....................

3-5

3-69.

Orifice Hole Burnishing Tool Installation .

..........

3-33

3-9.

Piston and Ring Assembly .

...........................

3-6

3-70.

Orifice Plug Burnishing .

....................................

3-33

3-10.

Connecting Rod Check .

................................

3-6

3-72.

Injector Push Rod Timing .

................................

3-33

3-11.

Ring Groove Wear Check .

............................

3-7

3-72.

Air Compressor Drive Gear Timing Mark .

.........

3-37

iii

Back to Top