TM-9-2815-213-34 - Page 9 of 192

*TM 9-2815-213-34

CHAPTER 1

INTRODUCTION

Section I. General

1-1. Scope

a

.

This technical manual contains instruction for

direct and general support maintenance of the Cummins

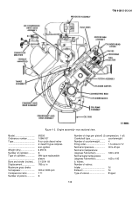

Diesel Engine, Model V8-300, (fig. 1-1 and 1-2). It

contains

descriptions

of,

and

procedures

for,

disassembly, inspection, repair, rebuild, and assembly of

the engine.

b

.

Appendix A contains a list of current refer ences,

including supply manuals, forms, technical manuals, and

other available publications applicable to the engine.

c

.

Appendix B lists repair parts, special tools, and

test equipment required for the performance of direct

and general support maintenance of the engine.

1-2.

Forms and Records

Maintenance forms, records, and reports which are to be

used by maintenance personnel at all maintenance

levels are listed in and prescribed by TM 38-750.

1-3.

Reporting of Equipment Publication

Improvement

The

reporting

of

errors,

omissions,

and

recommendations for improving this publication by the

individual user is encouraged. Reports should be

submitted on DA Form 2028, Recommended Changes to

Publications, and forwarded direct to the Commanding

General,

U.S.

Army

Tank-Automotive

Command

Attention: ASMTA-4, Warren, MI 48090.

Section II. Description and Data

1-4. Description

a.

General.

(1

) In this manual the following terms will be used to

identify the location for engine parts and assemblies:

(a)

Front-

fan end of engine.

(b)

Rear-

flywheel

end of engine.

(c)

Right and Left-

are

identified as viewed from

the rear.

(2

) The model V8-300 diesel engine is as eight

cylinder,

V-type,

Valve-in-head,

water

cooled,

compression-ignition engine, using the four stroke cycle

principle of operation. The four strokes consist of intake,

compression, power and exhaust. Intake and exhaust

valves, and fuel injectors, are operated from a single

camshaft. The intake stroke of the cycle brings filtered,

heated air to the cylinders. The compression stroke

compresses the air (17:1 compression ratio) to 500-600

p.s.i,

and

raises

the

cylinder

temperature

to

approximately 1000 degrees Fahrenheit. During the top

of the compression stroke and start of the power stroke,

a metered charge of diesel fuel is injected into the

cylinders. The high temperature within the cylinders

ignites the diesel fuel resulting in the power stroke. The

fourth stroke of the cycle exhausts the burned

gases from the cylinders. Proper engine operation

depends upon the high compression of the intake air and

the timed injection of the correct measure of diesel fuel

into the cylinder.

b.

Engine Assembly.

The model V8-300 engine

(fig. 1-1 and 1-2) is a diesel eight cylinder V-type, valve in

head, water cooled, compression ignition engine. The

engine is rated 300 horsepower at 3000 rpm and will

operate on diesel fuel.

c.

Engine Systems.

(1

) Fuel System. The system consists of a filter, fuel

pump with governor, fuel passages, and injectors (one

for each cylinder). The system is designed so that the

volume of liquid flow is proportionate to the fluid

pressure, the time allowed to flow, and the size of the

orifice fuel flows through. The pump draws fuel from the

vehicle supply tank and delivers it to each injector. A

governor controls the flow of fuel from the gear pump, as

well as the idle and maximum engine speed.

(2)

Lubrication System.

All working parts of the

engine are pressure lubricated. Oil is supplied by a dual-

type gear driven lubricating pump located below the

crankshaft and driven by the crankshaft gear. On

completion of the lubrication cycle, oil is accumulated in

the oil pan sump by gravity and is drawn from this sump

by the oil

1-1

Back to Top