TM-9-2815-213-34 - Page 13 of 192

*TM 9-2815-213-34

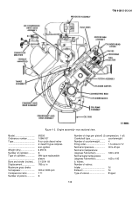

bearing cap to absorb crankshaft thrust loads. Dowel

pins are used to position each dowel pin half-ring.

(5)

Crankshaft gear.

A crankshaft gear is keyed to

the rear end of the crankshaft driving the gear train for

the camshaft and air compressor.

(6)

Vibration damper.

A vibration damper is

mounted to the forward end of the crankshaft to dampen

crankshaft vibrations. The unit consists of a rubber

damper hub and inertia member, both of which have

alinement marks and are matched when assembled. The

unit is further matched with alinement marks when

installed on the crankshaft to aid in dynamic balance.

(7)

Connecting rod with piston pin bushing.

The

connecting rod assemblies are two piece, I-beam, steel-

forgings split at the crankshaft end. Two piston pin

bushings are press fit into the rod at the piston end for

the floating-type piston pin. The pin is held in the piston

by two retaining rings.

(8)

Connecting

rod

bearings.

Connecting rod

bearings are steel backed, copper-lead, insert type, split

on the diameter. They are interchangeable and are

installed without reaming, scraping, or use of shims.

(9)

Pistons.

Aluminum alloy pistons are "barrel

ground", which provides a greater diameter at the thrust

surface than at the piston pin bosses. Pistons have three

piston rings (two compression and one oil). Compression

rings are located in the bottom groove. All rings are

located above the piston pin boss.

(10)

Camshaft.

A single camshaft positioned in the V-

section of the cylinder block directly above the

crankshaft, controls all valve and injector operations for

both banks. It is supported by five camshaft bushings

installed in the cylinder block. A camshaft thrust bearing

is installed at the gear (rear) end of the camshaft to

absorb thrust loads. Drilled oil passages in the cylinder

block lubricate the five camshaft bearings. The camshaft

gear is pressed and keyed to the rear of the camshaft

and is meshed (marked "O") with the crankshaft gear.

The camshaft is driven at one-half crankshaft speed.

The camshaft gear is meshed with the fuel pump and air

compressor drive gear at the upper rear portion of the

engine. The camshaft has twenty-four cams, eight

operate exhaust valves, eight operate intake valves, and

eight operate fuel injectors.

(11)

Cylinder

head.

Two

cylinder heads (one each

bank) are attached to the cylinder

block with 16 hold-down capscrews. Injectors and valves

are mounted in the cylinder head. Rocker levers and

bearing assemblies are located on top of each head on

pedestals.

(12)

Valves, valve springs, valve rocker levers,

bearings, and fuel injectors.

(a)

There are dual intake and exhaust valves

for each cylinder. Sixteen valve rocker levers with

bearing assemblies are mounted on the rocker lever

shafts. A cross-head moves two valves in unison from

pressure excited by the rocker lever. Right and left

movement comes from a push tube connected to the

cam followers. The cam followers ride on the lobe of the

camshaft. The valves and their companion crossheads

operate in replaceable guides. Valve springs are secured

to valve stems by valve spring retainers and locks.

Rocker lever shafts are supported by four rocker lever

brackets mounted on the cylinder heads.

(b)

Eight injector rocker levers and bearing

assemblies are mounted on the rocker arm shaft along

with the valve rocker assemblies. The injector is actuated

by the same method used to actuate the valve.

(13)

Flywheel with Ring Gear Assembly.

The flywheel

with ring gear assembly consists of a cast iron flywheel

with a replaceable steel ring gear. The flywheel is

attached to the rear of the crankshaft by means of a

crankshaft adapter using eight capscrews. The ring gear

meshes with the starter gear during the cranking

operation.

(14)

Oil Pump Assembly.

The oil pump installed

within the oil pan is of the positive placement gear type in

mesh with a gear train. Oil is drawn from the oil pan

sump through the oil pump inlet pipes (both suction and

scavenger lines) to the pump inlet ports. Oil is pumped

from the pressure pump under pressure through the

discharge port into various drillings in the block, cylinder

head, crankshaft, and rocker levers lubricating the

engine. The scavenger evacuates oil from the rear of the

oil pan and returns it to the main sump when the vehicle

is operating on steep grades. Oil pressure is maintained

by a regulator installed in the oil pressure pump.

1-5.

Tabulated Data

Refer to TM 9-2320-206-20 for tabulated data pertaining

to general characteristics and performance of the engine

assembly.

a.

General.

Manufacturer

Cummins Engine Company, Inc.

1-5

Back to Top