TM-9-2815-213-34 - Page 12 of 192

*TM 9-2815-213-34

degrees. Coolant flows from the thermostat housing to

the expansion tank in the radiator.

(4)

Air Intake System.

The V8-300 diesel engine is a

naturally aspirated engine. The air flows from the air

cleaner through connections into the air intake manifold

and is drawn into the combustion chamber.

(5)

Ventilation System.

Ventilation for the removal of

water and fuel vapor from the engine is accomplished by

the crankcase breather system. The combination

breather and pressurizing valve is located on the left

hand valve cover. During normal operation with valve in

the open position, crankcase ventilation is atmospheric.

For the deep water fording operation, valve is closed

manually to pressurize the engine crankcase.

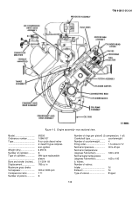

d.

Engine External Components.

(1)

Oil filler assembly and oil level gage.

The oil filler

cap is mounted on top of the left hand cylinder head

cover. The oil level gage is mounted on the front left of

the engine oil pan.

(2)

Sending units.

A sending unit mounted on the

engine oil cooler transmits engine oil pressure to the oil

pressure gage on the vehicle instrument panel. A

sending unit mounted to the thermostat housing

transmits the coolant temperature to the water

temperature gage on the vehicle instrument panel.

(3)

Water pump with pulley assembly.

The impeller

type water pump with pulley assembly, mounted on the

front of the cylinder head, is driven from the crankshaft

pulley assembly by one fan belt. The pump circulates

water from the bottom of the radiator through the engine

cooling system. The coolant fan is of the pull-type and

mounted to the idler pulley which is driven by the

crankshaft pulley.

(4)

Water temperature thermostat.

The water

thermostat is installed in a housing on the front of the

right cylinder head. Water leaving this housing goes to

the radiator expansion tank. The thermostat operates

from 173 degrees to 186 degrees Fahrenheit. A

thermostat by-pass line allows a limited circulation of

coolant when the thermostat is closed.

(5)

Exhaust manifolds.

The exhaust manifolds

installed on the right and left side of the engine, collect

exhaust gases from the eight cylinders and route it to two

exhaust pipe and muffler combinations located on each

side of the vehicle.

(6)

Intake Manifold Heater.

To aid in starting the

engine when the ambient temperature is 10 degrees

Fahrenheit or below, an intake air preheater is used. The

preheater equipment con-

sists of a hand-priming pump which pumps fuel into the

intake manifold, a glow plug which is electrically heated

by the battery, and a switch to turn on the glow plug while

fuel is pumped into the intake manifold. The fuel burns in

the intake manifold and heats the air.

NOTE

Refer to the, appropriate technical

manuals listed in Appendix A for a de-

tailed description of the engine starter

and alternator.

e.

Engine Internal Components

(fig.

13).

(1)

Cylinder block with bearing cap assemblies.

The

cylinder block with bearing cap assemblies which serve

as a crankcase, is a cast iron alloy. Wet-type cylinder

sleeves are installed in the cylinder block. Lubricating oil

passage ways extend the full length of the block and

supply oil to cylinder heads, crankshaft, and rocker

levels.

(2)

Oil pan.

The engine oil pan is cast aluminum and

contains a deep sump for 60% angularity operation. A

scavenge intake oil line attached to the double acting oil

pump (located at the flywheel end of the oil pan) extends

into the front sump, providing an intake for supplying the

necessary oil for lubrication.

(3)

Crankshaft.

The crankshaft, is a steel forging

with four integrally forged counterweights, five main

bearing journals, and four connecting rod bearing

journals. The crank throws are forged in two planes 180

degrees apart, with two throws in each plane. Cylinder

block oil drain passages provide lubrication to the

crankcase main bearing. Holes drilled diagonally through

the crankshaft and connecting rod bearing journals

provide direct passages for pressure lubrication of

connecting rod bearings. The crankshaft is statically and

dynamically balanced.

(4)

Crankshaft bearings and crankshaft thrust

bearings.

The five bearings supporting the crankshaft

are steel-backed, copper-lead, insert type, split on the

diameter so that each bearing half is interchangeable. A

small tang at the joint positions the bearings in the

cylinder block and bearing caps. Holes in the bearings

are alined with the oil passages in the cylinder block.

Grooves in the bearing surfaces aline with the drilled

holes in the crankshaft bearing journals to provide a

route for oil flow to connecting rod journals. Four

crankshaft thrust half-rings (bearings) are mounted on

both sides of the rear main

1-4

Back to Top