TM-9-2815-213-34 - Page 18 of 192

*TM 9-2815-213-34

NOTE

Special application studs have a nylok

insert for sealing the threaded opening.

The nylok insert end of the stud is in-

serted in the casting.

(3)

Oversize studs.

Only 0.003-inch oversize studs

are furnished for field replacement of studs in aluminum

castings. If a standard stud requires replacement, install

a 0.003-inch oversize stud. For identification purposes,

0.003-inch oversize studs are dipped in red dye.

NOTE

Studs may have a coarse thread on one

end and a fine thread on the other end.

The coarse thread end must enter the

aluminum casting. Studs having coarse

threads on both ends are used in

particular applications and normally the

short threaded end is in the casting.

Special application studs have a nylok

insert for sealing threads of studs. The

nylok insert end of stud is inserted in

casting. Marking on coarse thread end

of

stud determines when

stud

is

standard or oversize.

All replacement

studs have a special coating and must

have a small amount of mica-base anti-

seize compound applied on threads

before the stud is installed in casting.

Install replacement stud into opening

slowly to prevent overheating.

d.

Gears.

(1

) Replace all cracked gears.

(2

) Replace all gears which do not conform to

tolerances specified in repair and rebuilt standards,

paragraph 3-174.

(3

) Replace gears having worn, pitted, or galled

teeth. Remove sharp fins and burs from

gear teeth with a crocus cloth dipped in dry. cleaning

solvent or mineral spirits paint thinner.

e.

Bushings and Bushing-type Bearings.

When

bushings and bushing-type bearings are damaged or

worn beyond the limits specified in paragraph 3-174,

generally the mating parts with which they are used must

also be replaced. Reference to (1) and (2) below will be

made in the rebuild section for the particular part when

replacement of bushings and bushing-type bearings is

required.

(1)

Removal.

Remove bushings or bushing-type

bearings by pressing out part with suitable arbor press or

with the special tools provided.

(2)

Installation.

Clean repaired parts thoroughly

before assembly or installation. Aline bushing or bushing-

type bearing in casting or retaining cage and press into

place with a suitable arbor press or with the special tools

provided.

(3)

Reaming.

The bushing-type bearings in oil pump

must be finish reamed after installation to size specified

in repair and rebuild standards. All other bushing-type

bearings are machined for proper clearance and do not

need reaming.

f.

Oil Seals.

Oil seals must be replaced when thin

feather edge is damaged or when seal material has

become hard or brittle.

(1)

Removal.

Press or pry damaged oil seal from

casting or housing, being careful not to damage bore in

casting or housing.

(2)

Repair.

When oil seal bore in casting is burred or

damaged to a point where an oil-tight seal is impossible,

replace

casting.

Remove slight nicks, burs, and

scratches from bore in casting with crocus cloth dipped

in dry-cleaning solvent or mineral spirits paint thinner.

(3)

Installation.

Install new oil seal in bore of casting

or adapter, using a suitable oil seal replacer tool.

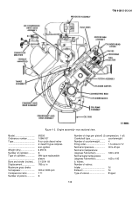

Section III. Removal of Engine Components

2-8.

General

a.

Removal and Installation.

The instructions for

removal and installation of engine components have

been arranged in the most logical order of removal for

complete engine disassembly. Installation in general,

shall be the reverse order of the removal instructions. To

facilitate the removal, and later disassembly, assembly

and

installation procedures, the components are

separated into categories, (i.e., external components,

and internal components).

b.

External Components.

External components are

defined as the basic units of the engine sys-

tems, (i.e., cooling, fuel, electrical, drive, intake, exhaust,

hydraulic, and air, that are externally attached to the

engine).

c.

Internal Components.

Internal components are

defined as the units and assemblies within the engine

block and oil pan, the cylinder heads and associated

parts, and block.

2-9.

Engine Preparation

NOTE

Check to insure that coolant and lube oil

has been completely removed from

engine.

2-3

Back to Top