TM-9-2815-213-34 - Page 24 of 192

*TM 9-2815-213-34

Figure 2-12.

Cylinder head covers-removal/installation.

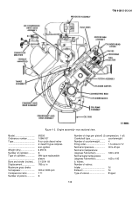

Figure 2-13. Crankcase breather

tube-

removal/installation.

(c) Remove ten capscrews, lockwashers, and flat

washers securing cover to cylinder head.

(d) Remove cover, breather and pressurizing unit,

and gasket.

b.

Push Rod Cavity Covers

(fig. 2-14).

(1) Remove 26 capscrews, lockwashers, and flat

washers securing each cover to cylinder heads.

(2) Remove covers and gaskets.

c.

Rocker

Arms and

Push Rods

(fig. 2-15)

(1) Loosen all push rod adjusting screw locknuts

and back-off adjusting screws.

(2) Secure rocker arms with rubber bands.

(3) Remove ten capscrews and flat washers

securing each irocker arm to respective cylinder head.

(4) Remove rocker arms and brackets.

Figure 2-14. Push rod cavity covers-

removal/installation.

(5) Remove 24 push rods (16 valve and 8 injector)

from tappets.

d.

Fuel Injectors

(fig. 2-16).

(1) Remove eight capscrews and flat washers and

nylon inserts securing injector clamps to cylinder head.

(2) Remove clamps.

(3) Pull injectors from cylinder head (fig. 2-17).

e.

Valve Crossheads

(fig. 2-18). Remove sixteen

crossheads by lifting each straight up from guides.

f.

Cylinder Heads

(fig. 2-19).

(1) Attach cylinder head lifting plate (45, fig. B-28).

(2) Attach lifting hook of chain fall, or other suitable

lifting device, to lifting plate. Take-up slack in chain or

cable.

(3) Remove 16 capscrews and flat washers (fig. 2-

18) securing heads to block (eight cap screws per head).

(4) Using lifting device remove each cylinder head.

Remove gaskets.

g.

Valve and Injector Tappets

(fig. 2-20).

(1) Remove 16 capscrews and lockwashers (eight

per cylinder head) securing eight tappet guide plates to

heads (four per head).

(2) Remove guide plates.

(3) Lift tappet assembly from block.

h.

Flywheel

(fig. 2-21).

(1) Cut lockwire on six capscrews securing flywheel

to crankshaft adapter.

(2) Remove two opposing capscrews.

(3) Insert two 5/8 x 6-inch headless studs in

2-9

Back to Top