TM-9-2815-225-34-P - Page 350 of 736

TM 9-2815-225-34&P

0041 00

0041 00-4

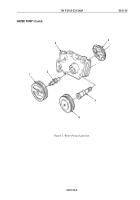

WATER PUMP (Contd)

CLEANING AND INSPECTION

1.

For general parts cleaning information, refer to CLEANING, WP 0051 00.

2.

For general parts inspection information, refer to INSPECTION, WP 0051 00.

NOTE

Replace any part that does not pass visual inspection or is

outside specified wear limits.

3.

Inspect water pump pulley (1) and idler pulley (6) for cracks, chips, or damaged pulley grooves.

4.

Inspect water pump housing (3) for cracks, corrosion, and stripped or elongated bolt holes. Repair

any stripped holes.

5.

Inspect water pump housing (3) weep hole for blockage. Clean weep hole if blocked.

6.

Using inside micrometer, measure water pump housing (3) bearing bore. Discard water pump

housing (3) if bearing bore is larger than 2.45 in. (62.22 mm).

7.

Inspect impeller (4) for cracks, chips, or corrosion.

NOTE

Impeller must be 0.001 in. (0.025 mm) smaller than water

pump shaft impeller end to maintain a press fit between

components. Discard all parts that are out of specifications.

8.

Using micrometer, measure water pump shaft impeller (4) end outside diameter. Diameter

should be 0.6262–0.6267 in. (15.905–15.918 mm).

9.

Using micrometer, measure water pump shaft (2) pulley end outside diameter. Diameter should

be 0.6693–0.6696 in. (17.000–17.008 mm).

NOTE

Water pump pulley must be 0.001 in. (0.025 mm) smaller than

water pump shaft pulley end to maintain a press fit between

components. Discard all parts that are out of specifications.

10.

Using inside micrometer, measure water pump pulley (1) bore inside diameter. Diameter should

be 0.6663–0.6673 in. (16.924–16.949 mm).

11.

Using inside micrometer, measure impeller (4) bore inside diameter. Diameter should be

0.624–0.625 in. (15.85–15.88 mm).

12.

Inspect water pump shaft (2) and idler shaft (5) for cracks, bends, or damaged threads.

Back to Top