TM-9-2815-225-34-P - Page 478 of 736

TM 9-2815-225-34&P

0050 00

0050 00-4

BIG CAM III MODIFICATION KIT INSTALLATION INSTRUCTIONS (Contd)

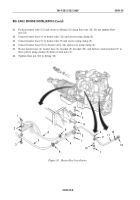

Figure 4. Big Cam I Flywheel Housing and Flywheel Installation.

FLYWHEEL HOUSING

GUIDE PIN

1

2

7

6

5

4

3

A

C

E

B

D

F

8

BIG CAM III INSTALLATION PROCEDURES (Contd)

4.

Install two flywheel housing guide pins on Big Cam III engine (1).

5.

Install Big Cam I flywheel housing (2) on Big Cam III engine (1) with seven of nine screws (6) and

washers (7). Tighten screws (6) 10–20 lb-ft (14–27 N

•

m).

6.

Remove two flywheel housing guide pins from Big Cam III engine (1) and install two remaining

screws (6) and washers (7) on Big Cam I flywheel housing (2). Tighten screws (6) 10–20 lb-ft

(14–27 N

•

m).

7.

Install two 5/8–18x6 in. guide studs in opposite holes on Big Cam III crankshaft (8) until fully seated.

8.

Apply lubricating oil to threads of screws (4) and face of washers (3). Allow excess oil to drain

from screw threads.

9.

Install Big Cam I flywheel (5) on Big Cam III crankshaft (8) with four screws (4) and washers (3).

Tighten screws (4) hand-tight in sequence shown in figure 4.

10.

Remove two guide studs and install two remaining screws (4) and washers (3) on Big Cam I

flywheel (5). Tighten screws (4) 70 lb-ft (95 N

•

m) then 140 lb-ft (190 N

•

m) and finally 200–220 lb-

ft (271–298 N

•

m) in sequence shown in figure 4.

NOTE

The flywheel must be pushed toward front of engine to remove

crankshaft end clearance when crankshaft is rotated and

measurements are taken. If total indicator readings exceed

limits, remove flywheel; clean flywheel and crankshaft flange

faces, install, and repeat runout checks.

11.

Install dial gauge attachment and dial indicator on Big Cam I flywheel housing (2).

12.

Position contact tip of dial indicator against wide diameter of Big Cam I flywheel (5) bore and set

dial indicator to zero. Rotate crankshaft (8) one complete revolution. Total indicator reading must

not exceed 0.005 in. (0.127 mm).

13.

Inspect Big Cam I flywheel (5) face runout and install or reposition dial indicator on Big Cam I

flywheel housing (2).

14.

Position contact tip of dial indicator against face of Big Cam I flywheel (5) as close to outside

diameter as possible. Rotate crankshaft (8) one complete revolution. Total indicator reading must

not exceed 0.005 in. (0.127 mm).

15.

Install Big Cam III engine in vehicle. Refer to WP 0048.

Back to Top