TM-9-2920-242-35 - Page 34 of 110

FIGURE 20. TESTING ARMATURE FOR

(4)

(5)

GROUNDS.

ture slowly in the growler. A short cir-

cuit will pull the steel strip tightly

against the armature core and cause the

strip to vibrate. If a short circuit is

found, the armature must be replaced.

Inspect armature shaft and commutator

for runout using a lathe or "V" blocks

and a dial indicator (fig. 22). If the run-

out does not conform to wear limits

(par. 41f), the commutator must be re-

surfaced providing the diameter will not

be below the limits specified in wear

limits. If refinished diameter of com-

mutator exceeds the limit, the armature

must be replaced.

Inspect armature shaft splines for wear

or damage. Replace the armature if the

splines are defective.

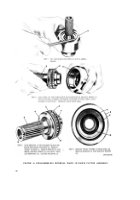

FIGURE 21. TESTING ARMATURE FOR

SHORT CIRCUITS USING A GROWLER.

color. If the contact surface is rough,

pitted, scored, burned, or coated with

hard carbon or oil, the commutator must

be resurfaced. If mica is not 0.025 to

0.032 inch below surface of commutator,

it must be undercut to the correct depth.

(6)

Inspect the commutator contact surface.

A satisfactory condition is indicated by

an even, highly burnished, dark-copper

FIGURE 22. CHECKING

COMMUTATOR RUNOUT.

25

Back to Top