TM-9-2920-242-35 - Page 33 of 110

f. Brushes. Clean brushes with a clean, dry

cloth only. Do not permit dry cleaning solvent

to contact the brushes.

26. INSPECTION

a. Inspection of Drive Housing.

(1)

(2)

(3)

(4)

(5)

(6)

Inspect drive housing for cracks and

distortion. Replace housing if defective.

Inspect housing for scratches, burs, and

nicks on machined surfaces. Repair as

necessary (par. 27a).

—

Inspect threads in tapped holes in hous-

ing for damaged threads. Replace hous-

ing if threads are stripped or damaged

beyond repair.

Inspect sleeve bearing for discoloration,

rough spots, score marks, scratches,

and nicks.

Check inside diameter of sleeve bearing.

Replace bearing if it does not conform

to limits specified in wear limits (par.

41e) . If sleeve bearing is removed,

check bearing bore in housing. Replace

housing if bore does not conform to

limits specified in wear limit (par. 41e).

Note. Appendix II, Repair Parts, lists

a sleeve bearing set to be used in re-

pair of the starter.

Inspect wick for tears, fraying, or wear.

Replace wick if defective.

b. Inspection of Commutator End Plate.

(1)

(2)

(3)

(4)

Inspect commutator end plate for cracks

and distortion. Replace plate if defec-

tive.

Inspect end plate for scratches, burs,

and nicks on machined surfaces.

Inspect threads in tapped holes of end

plate for damage. Replace end plate if

threads are stripped or damaged beyond

repair.

Inspect sleeve bearing for discoloration,

rough spots, score marks, scratches;

and nicks.

(5)

(6)

Check diameter of sleeve bearing. Re-

place bearing if it does not conform to

limits specified in wear limits (par.

41e) . If sleeve bearing is removed,

check bearing bore in end plate. Replace

end plate if bore does not comform to

limits specified in wear limits (par.

41e).

—

Note. Appendix II, Repair Parts, lists

a sleeve bearing set to be used in re-

pair of the starter.

Inspect wick for tears, fraying, or wear.

Replace wick if defective.

c. Inspection of Brush Holder Assembly and

Brushes.

(1)

(2)

(3)

Check insulation, spacers, plates, and

brush holders for distortion and cracks.

Replace defective parts.

Check brushes and springs for cracks

or breaks. Check brush spring tension

(step 1, fig. 10) for conformity to wear

limits (par. 41a) . If any brushes are

defective, replace entire set with brush

kit. Replace springs if they do not con-

form to wear limits.

Inspect terminal plate stud for damaged

threads.

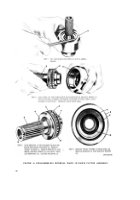

d. Inspection of Armature.

—

(1)

(2)

(3)

Check armature shaft and commutator

for conformity to wear limits (par. 41e).

Replace the armature if worn beyond

limits specified.

Inspect armature for grounds with a test

light by touching one of the test probes

to the armature core and the other probe

to one of the commutator bar risers

(fig. 20). Test all commutator bars in

this manner. If the test light glows, the

armature is grounded and must be re-

placed.

Inspect armature for short circuits

using a growler fixture. Place the ar-

mature in the growler as shown in fig-

ure 21. Hold a thin strip of steel, such

as a hacksaw blade about 1/32 inch

away from armature. While holding the

steel strip in position, rotate the arma-

24

Back to Top