TM-9-2920-242-35 - Page 38 of 110

(2)

(3)

tator against limits specified in wear

limits (par. 41f) and undercut mica ((2)

below) if refinished commutator is with-

in limits specified. Replace armature

if commutator does not conform to

measurements specified.

Undercutting mica. After resurfacing

the commutator, undercut mica to a

depth of 0.025 to 0.032 inch below the

surface of the commutator using a

power-driven undercutting tool (fig. 25).

If a power-driven tool is not available,

the mica may be undercut by hand as

shown in figure 26.

Note. Use care in undercutting. Do not

widen commutator slots by removing

metal from segments, and do not leave

thin edge of mica next to segments.

Figure 26 illustrates examples of good

and bad undercutting.

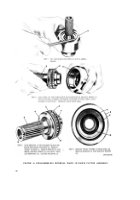

Polishing commutator. After the mica

has been undercut, remove all copper

and mica particles with compressed air.

Polish the commutator in a lathe with

No. 2/0 sandpaper (fig. 27) while the

armature is rotating at 1500 rpm. After

polishing the armature, check that the

diameter is within the limits specified

in wear limits (par. 41f).

e. Repair of Drive Clutch.

(1)

(2)

(3)

Smooth burs, nicks, and rough spots on

splines and pinion teeth using a fine

stone or crocus cloth dipped in dry

cleaning solvent.

Smooth rough spots, scoring, scratches,

and nicks on inside bore of sleeve bear-

ings and all surfaces of bronze bearings

using crocus cloth dipped in dry clean-

ing solvent.

Smooth minor rough spots, nicks, and

scratches on internal polished surface

of shell using a fine stone or crocus

cloth dipped in dry cleaning solvent.

If nicks and scratches cannot be re-

moved or surface cannot be restored

to original finish, replace the shell.

f. Repair of Lever Housing.

(1)

(2)

(3)

Smooth minor scratches, burs, and

nicks on machined surfaces of lever

housing using a fine mill file.

Repair damaged threads in housing.

Smooth minor rough spots, scoring,

scratches, and nicks on inside bore of

sleeve bearing using a fine stone or

crocus cloth dipped in dry cleaning sol-

vent.

FIGURE 27. POLISHING COMMUTATOR

WITH SANDPAPER.

g. Repair of Shift Lever, Shaft and Solenoid

Plunger.

(1) Smooth minor rough spots, scratches,

and nicks on clutch contact surfaces of

shift lever using a fine stone. Smooth

minor rough spots, scratches, and nicks

on lever shaft

(2) Repair damaged

h. Repair of Frame.

—

(1)

(2)

using a fine stone.

threads on plunger rod.

Smooth minor scratches, burs, and nicks

on machined surfaces of frame using a

fine mill file.

Repair damaged threads in frame. Re-

pair damaged threads on field coil ter-

minal stud.

29

Back to Top