TM-9-6920-430-14 - Page 76 of 180

TM 9-6920-430-14

Section IV. PROOF PRESSURE TEST PROCEDURE

3-6. GENERAL.

The proof pressure test will be performed upon receipt, every six (6)

months thereafter, or at any time a malfunction or erratic operation indicates the need.

The test ensures that the safety relief valve, pressure switches, pressure gages and high

pressure service hoses are not defective.

Before proof testing, perform Before (B)

Preventive Maintenance Checks and Services in accordance with table 3-1 (page 3-7).

The inlet, outlet, and proof test hoses will have a maximum total life of five years from the

initial proof test date on the manufacturer’s identification tag attached to one end of the

hose.

NOTE

All hoses in storage with test dates older than 12 months will be tested prior

to use. Any hose that fails test will be disposed of immediately. If the GPU

does not operate within the tolerances as stated in this procedure, return the

GPU to the depot for repair.

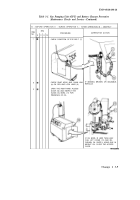

3-7. PREPARING THE CPU FOR HIGH PROOF PRESSURE TEST.

Death or serious injury may result if you fail to observe the safety

precautions. The proof test should be performed in a well ventilated room

with a protective blast enclosure, or have a minimum wall construction of

8-inch width reinforced concrete block or equivalent. The GPU should beat

least four (4) feet from any wall. The operator should be outside the room

containing the GPU and positioned behind a protective wall at a distance as

far as the control cable will allow. The area within 100 feet of the GPU room

should be cleared of all personnel. If the GPU is installed in an area that

does not conform to above requirements, place sand bags of minimum

thickness of 16 inches around the GPU. The bags should be placed 2 feet

from the GPU and 4 feet high. In this case the area should be cleared of all

other personnel for a minimum distance of 300 feet. High gas pressure (up

to 8000 psig) exists when performing the proof test procedure.

The 5/8-inch 9/16-inch, 1/2-inch and 7/16-inch wrenches used in this

procedure must be open-end type, not more than 8 inches long, and in near

new condition. Wrenches longer than 8 inches in length can cause excessive

tightening to over-stress or break the high pressure fittings which, in turn,

can result in death or injury to personnel.

3-16

Change 1

Back to Top