SMI-9-2320-387-14P-1 - Page 183 of 671

SMI 9-2320-387-14&P-1

Change 4

11-108.15

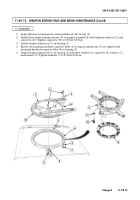

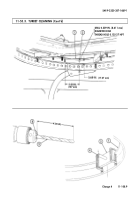

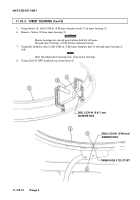

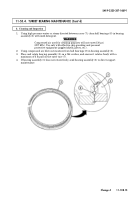

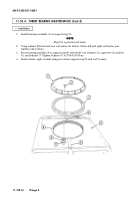

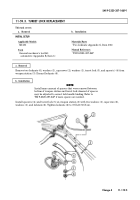

11-55.4. TURRET BEARING MAINTENANCE (Cont’d)

1.

Using high pressure water or steam directed between races (7), clean ball bearings (8) in bearing

assembly (3) with mild detergent.

WARNING

Compressed air used for cleaning purposes will not exceed 30 psi

(207 kPa). Use only with effective chip guarding and personal

protective equipment (goggles/shield, gloves, etc.).

2.

Using compressed air, blow out moisture from ball bearings (8) in bearing assembly (3).

3.

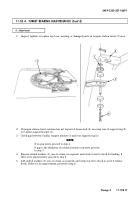

Place and rotate bearing assembly (3) on a flat surface, and ensure it rotates freely with a

maximum of 6 lb pull on the outer race (7).

4.

If bearing assembly (3) does not rotate freely, send bearing assembly (3) to direct support

maintenance.

b.

Cleaning and Inspection

Back to Top