TM-5-2330-378-14-P - Page 310 of 524

TM 5-2330-378-14&P

5-19. GOOSENECKHINGEPINREPLACEMENT(M870).

ThisTaskCovers:

a.

Removal

b.

Installation

Initial Setup:

Tools/Test

Equipment:

Equipment

Conditions:

• Common

no. 1 tool set (item 6, Appendix

B)

Gooseneck in upright position (para 2-8).

• Crane, wheel mounted (Item 2, Appendix B)

• Field maintenance tool set (Item 4, Appendix B)

Personnel Required:

Two

• Tool kit, general mechanic's:

automotive

(item 7, Appendix B)

References:

TC 9-237

Materials/Parts:

- Retaining ring (item 24,

Appendix 1)

a.

REMOVAL

1.

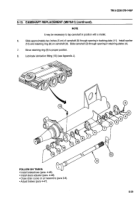

Using crane, lift front of semitrailer.

2.

Place two one-foot-high wood blocks (1) under two landing pads (2). Lower front of semitrailer onto blocks

(1).

3.

Cut tack weld from retaining ring (3) behind semitrailer frame (4) on gooseneck hinge pin (5). Removeretaining

ring (3) from hinge pin (5). Grind weld to surface of hinge pin (5). Discard retaining ring.

4.

Using crane, lift gooseneck (6) until two locking pins (7) are loose.

WARNING

Do not work under gooseneck unless lockpins are in place. Working under goose-

neck when lockpins are not in place could result in injury or death.

5.

Remove two lockpins (para 2-10).

6.

Lower gooseneck (6) until fully extended.

WARNING

Placement of jacks is extremely important in this procedure. Failure to place jacks

properly could result in injury or death.

7.

Place hydraulic jack under front and rear ends of upper deck side rail (8).

8.

Raise hydraulic jack at front of side rail (8) until gooseneck (6) starts to lift.

9.

Raise hydraulic jack at rear of side rail (8) until hinge pin (5) can be turned with pipe wrench.

10.

Remove lubrication fitting (9) from hinge pin (5).

NOTE

Removal of hinge pin requires the use of a slide hammer. Use a nut that will fit threads

on slide hammer rod.

11.

Put nut (10) in place over lubrication fitting hole (11) and have assistant hold it in place with wooden dowel.

Weld nut (10) to hinge pin (5).

5-48

Back to Top