TM-5-3805-254-14-P-2 - Page 748 of 894

TRUCK SERVICE MANUAL

TRANSMISSION

Para 6-4

HT 700D SERIES TRANSMISSIONS

(10)

Remove eight bolts 44while holding trimmer

cover 43 against spring pressure.

Relieve pressure and

remove cover 41.

(11)

Remove springs 27 and 28, valve stop 29,

trimmer plug 26, and trimmer valve 25.

(12)

Remove springs 32 and 33, stop 34, plug 31,

and valve 30.

(13)

Remove springs 37 and 38, stop 39, plug 36,

and valve 35.

(14)

Remove valve 42, spring 41 and stop 40.

(15)

Remove springs 47 and 48, stop 49, plug 46

and valve 45.

NOTE

In operations (16) through (24), below, the

components i n each bore are spring-loaded,

and must be restrained while removing the

retainer pins.

Also, before removing retainer

pins in operations (20), (21) and (22), the

adjusting rings must be marked, and each

identified with its bore, so they can be

reassembled into the same bores and at the

same positions in the bores.

(16)

Remove retainer pin 50, valve stop 54, spring

53, and valve 52.

NOTE

In earlier models, valve stop 54 consisted of two

separate pieces.

(17)

Remove retainer pin 51, spring spacer 57,

spring 56, and valve 55.

(18)

Remove retainer pin 63, spring 61, stop 62

and valve 60.

(19)

Remove retainer pin 72, valve plug 71, spring

69, valve stop 70, and valve 68.

(20)

Remove retainer pin 75, adjusting ring 80,

spring 78, valve stop

79, and valves 77 and 76.

(21)

Remove retainer pin 86, adjusting ring 85,

spring 83, valve stop 84, and valves 82 and 81.

(22)

Remove retainer pin 92, adjusting ring 91,

spring 89, valve

stop 90, and valves 88 and 87.

(23)

Remove retainer pin 96, valve stop 95, spring

94, and valve 93.

NOTE

In earlier models, valve stop 95 consisted of two

separate pieces.

(24)

Remove retainer pin 100, spring 98, valve stop

99, and valve 97.

NOTE

Refer to paragraph 6-2, above.

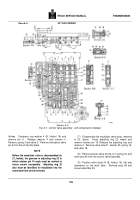

b. Assembly (B, foldout 16)

NOTE

Check the position of all valve assembly

components, the configuration of all valves and

plugs, and the identification of all springs before

installation.

Refer to figure 6-7 for position and

configuration of components.

Refer to the

spring chart in Section 8 for identification of

springs.

(1)

Install components into bores A and B (fig. 6-

7), in the sequence indicated by numbers 1 through 5.

NOTE

All valves must move by their own weight (dry)

when installed.

(2)

Install spring spacer 57 and valve stop 54 (B,

foldout 16) into bores A and B (fig. 6-7).

Depress the

springs and install retainer pins 51 and 50 (B, foldout 16)

to retain spacer 57 and valve stop 54.

NOTE

In earlier models, valve stop 54 consisted of two

separate pieces.

(3)

Install components into bores C, D and E (fig.

6-7), in the sequence indicated by numbers 6 through 17.

(4)

Install components into bore F, in the

sequence indicated by numbers 18 through 22.

(5)

Install components into bore S (fig. 6-7), in

sequence indicated by numbers 65, 66 and 67.

(6)

Install trimmer cover 43 (B, foldout 16).

Compress the springs, and retain the cover with eight

1/4-20 x 5/8-inch bolts.

741

Back to Top