TM-5-3805-254-14-P-2 - Page 745 of 894

TRUCK SERVICE MANUAL

TRANSMISSION

INSPECTION AND REBUILD

Para 6-3/6-4

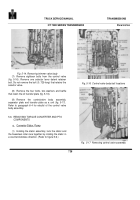

Fig. 6-6.

Ball locations for control valve.

(10)

If ball bearing 6 (B, foldout 7) was removed,

press it onto the hub of turbine 7.

(11)

Carefully center the lockup clutch plate in the

flywheel.

Install the torque converter turbine, engaging

its hub splines with the internal splines of the lockup

clutch plate.

Seat the ball bearing in its bore.

6-4.

CONTROL VALVE BODY ASSEMBLY

CAUTION

The valve body assembly contains a number of

springs, some of which are similar and can be

mistakenly interchanged.

Also, springs vary in

valve bodies used on different models.

If

springs are not reinstalled in the same locations

from which removed, the calibration of valve

body functions will be lost.

For these reasons, it

is recommended that each spring, at removal, be

tagged with its item number in B, foldout 16.

This will simplify correct reassembly of the valve

body components.

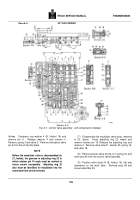

a. Disassembly (B, foldout 16)

(1)

If not removed previously, remove manual

selector valve 72.

Stop bolt 62 must be removed before

valve 72 can be removed.

(2)

Position the valve assembly, modulator

upward (fig. 6-5).

Remove three bolts that retain the

modulator valve body, while holding the oil transfer plate

and separator plate together.

(3)

Lift off the modulator valve body and set it

aside, while retaining a grasp on the oil transfer and

separator plates.

(4)

Invert the oil transfer and separator plates

while holding them firmly together.

Lay them on the work

table.

(5)

Lift the separator plate off the oil transfer plate.

Compare check ball locations in the transfer plate to

those in the chart (shown in fig. 6-6), Make a sketch or

list that will identify the ball sizes and locations (for

reassembly).

Remove the balls.

(6)

Remove the lubrication pressure regulator

valve from the oil transfer plate as

738

Back to Top