TM-5-3895-372-20 - Page 28 of 694

TM 5-3895-372-20

Section VI CEMENT SYSTEM

2-13.

INTRODUCTION.

The cement system is calibrated to deliver cement at a known, constant rate, while the other ingredients are varied to

produce different mixes.

For information about the cement bin vibrators, see Section IX.

2-14.

DESCRIPTION.

1.

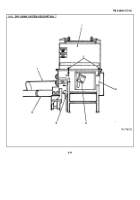

CEMENT BIN.

Holds 63 cu ft (1.76

m3)

of dry cement.

2.

QUICK-LOADING HOPPER.

Mounted on cement bin top.

Small top opening to accept "elephant trunk,"

removable lid for bulk loading.

Lid gasket seals out moisture.

3.

VIBRATOR.

Shakes screen to sift cement during loading.

Powered by compressed air from chassis air

reservoirs.

Air line equipped with quick-disconnect fitting.

4.

SCREEN.

Breaks up cement and strains out large lumps during loading.

Connected to

5.

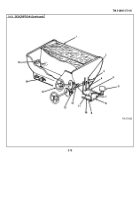

CEMENT BIN AUGER.

Loosens cement and channels it into meter-feeder.

Auger blades at ends carry

cement to center.

Fingers in center break up packed cement.

Supported by hardwood bearing block.

6.

AlR PADS (2).

Loosen settled cement with blasts of air.

Air pases through cloth pads held by metal screens.

7.

FLUFFER AIR LINES.

Carry pressurized air to air pads.

8.

FLUFFER CONTROL VALVE.

When operated, allows dry air from filter to go to air pads.

9.

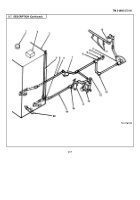

CEMENT METER DRIVE CHAINS.

Driven by sprockets on conveyor drive shaft.

Turn cement bin auger and

meter feeder.

Actuated automatically when main clutch is engaged.

10.

CEMENT FEEDER CLUTCH.

Normally engaged.

When disengaged allows cement meter to be turned

independently of sand and stone conveyor.

Dog type clutch.

11.

SPRING TINE ASSEMBLY.

Knocks cement out of meter pockets Spring tension causes hammers on tines to

snap against turning meter wheel.

12.

METER REGISTER CABLE.

Connects meter-register to feeder.

13.

METER REGISTER.

Shows units of cement delivered.

Large resettable readout indicates cement delivered

per job.

Smaller readout shows total cement delivered.

14.

CEMENT METER-FEEDER.

Measures and delivers cement from bin to conveyor belt.

Cement is carried in

pockets of rotating wheel.

Exact capacity varies between units, but will be approximately 2.4 cu ft/min (0.067

m

3

/min).

15.

BEARINGS (5).

Support cement bin auger and meter-feeder shaft.

Allow them to turn freely.

2-14

Back to Top