TM-5-3895-372-20 - Page 30 of 694

TM 5-3895-372-20

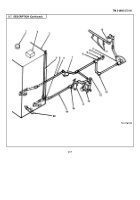

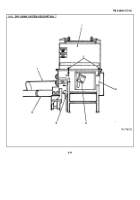

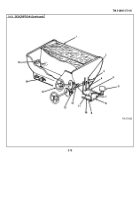

Section VII MIXER-AUGER SYSTEM

2-15.

INTRODUCTION.

The mixer-auger combines the wet and dry ingredients to make concrete.

The system consists of a hydraulically-powered

auger turning in the mixer trough.

(Further information about the hydraulic motor may be found in Section VI II).

The

assembly is raised and lowered by an electric winch (Section X).

2-16.

DESCRIPTION.

1.

SWIVEL ASSEMBLY.

Supports front of mixer assembly.

Fixed frame is bolted to main body.

Rotating ring

holds trough, allows it to pivot on swivel frame.

2.

MINISKIRT.

Rubber guard channels concrete ingredients from conveyor into mixing trough.

3.

TROUGH

COVERS.

Prevent splashing and protect personnel from auger.

Lift up for access to auger.

4.

HYDRAULIC MOTOR.

Turns auger.

Driven by hydraulic pump.

5.

AUGER DRIVE BUSHING.

Connects auger core to hydraulic motor.

6.

RUBBER BOTTOM.

Flexible trough bottom "gives" to prevent auger from breaking on lumps and large

stones.

7.

TROUGH FRAME.

Metal frame supports rubber bottom, hydraulic motor, and auger.

Held to swivel ring by a

cotter-key and pin assembly.

Can be swung left or right to about 850.

8.

BLADES (8).

Replaceable blades protect ends of flighting.

(Bolted on.)

9.

SECTIONAL BLADES (9).

Replaceable blades protect flighting edge.

(Bolted on.)

10.

PADDLES (26).

Mix aggregates, cement, water, and admixture to form concrete.

A replaceable wear paddle

bolts onto each paddle.

11.

FLIGHTING.

Spiral blades push concrete through mixing trough as auger turns.

Welded to auger core.

Flighting is reinforced by replaceable blades and sectional blades.

12.

MIXING AUGER.

Mixes concrete ingredients, carries them to rear of trough.

Paddles and flighting are

welded onto core of hollow pipe.

Pipe has 21/ in.

(5.7 cm) outside diameter, 7 ft (2.1 meters) long.

13.

BEARING.

Supports front end of auger.

Allows it to turn freely.

14.

INCLINOMETER.

Indicates angle of elevation of mixing trough.

Auger is normally operated at a 15° - 25°

angle.

2-16

Back to Top