TM-5-3895-372-20 - Page 34 of 694

TM 5-3895-372-20

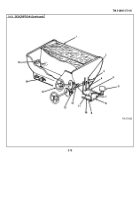

Section IX AIR SYSTEM

2-19. INTRODUCTION.

The mixer body air system draws pressure from the chassis air reservoir.

A safety valve at the reservoir cuts off the

mixer body air supply if reservoir pressure drops below 65 psi (448 kPa).

NOTE

The cement screen vibrator is described in para 2-14.

2-20. DESCRIPTION.

1.

VIBRATORS (4).

Shake the sand and cement bins.

Keep aggregates and cement loose; prevent bridging.

(Two on each bin.)

2.

AIR PADS (2).

Loosen settled cement with blasts of air.

3.

CEMENT SCREEN VIBRATOR AIR LINE.

Carries lubricated air to quick-disconnect fitting for cement

screen vibrator (see para 2-14).

4.

MANUAL VIBRATOR CONTROL.

Allows manual activation of aggregate bin vibrators.

Handle connects to

rear vibrator air valve.

5.

AIR LUBRICATOR.

Sprays fine oil mist into vibrator air lines.

Should be adjusted to one drop every 3rd

vibration.

6.

FLUFFER CONTROL VALVE.

Manually operated valve controls air supply to air pads.

Mounted "upside

down" to prevent cement dust from clogging valve.

7.

AUXILIARY AIR HOSE.

May be used on air fittings of water system to blow moisture out in cold weather.

8.

Al R FILTER.

Removes moisture from incoming air.

Petcock in bottom for draining trapped liquid.

9.

GATE VALVE.

Controls air flow from chassis reservoir to mixer body air system.

10.

LIQUID ADMIX AIR SUPPLY LINE.

Carries dry air from filter to liquid admix system (para 2-9).

11.

VIBRATOR AIR VALVES.

Control air supply on vibrators.

Mounted above cam attached to cement meter-

feeder.

Open when contacted by cam lobe.

2-20

Back to Top