TM-5-3990-263-13-P - Page 326 of 728

Table

1.

Operator Preventive Maintenance Checks and Services - Continued

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

6

5

5

1

2

3

4

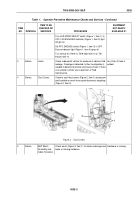

Figure 3.

BAP Winch Assembly.

Check winch hydraulic pump (Figure 3, Item 2) and

hoses (Figure 3, Item 3) for leaks or damage.

Any Class III leaks are

detected. Winch is

damaged or parts are

missing.

Check winch frame locking levers (Figure 3, Item 4) for

damage or missing parts.

Locks are damaged or will

not operate.

Check sheave assembly and roller and pulley grease

fittings (Figure 3, Item 5) for damaged or missing

hardware.

Rollers are damaged or

binding.

Check cable tensioner sheaves (Figure 3, Item 6) for

damage.

Sheaves are damaged or

missing.

6

Before

BAP Hold-Down

Lock

Check lock (Figure 4, Item 1) for damage or missing

parts.

TM 5-3990-263-13&P

0035

0035-4

Back to Top