TM-5-3990-263-13-P - Page 329 of 728

Table

1.

Operator Preventive Maintenance Checks and Services - Continued

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

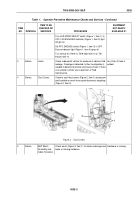

10

Before

Center Roller

Assembly

Inspect center roller assembly (Figure 8, Item 1) for

damage and freedom of movement.

Center roller is damaged

or will not move properly.

2

3

1

Figure 8.

Center Roller.

Inspect hydraulic pump assembly (Figure 8, Item 2) for

proper operation:

•

Position select lever (Figure 8, Item 3) to center

roller position (up).

•

Pump hydraulic pump assembly (Figure 8, Item

2), and ensure center roller assembly (Figure

8, Item 1) is free to move.

•

Position select lever (Figure 8, Item 3) to OFF

position (center).

Hydraulic pump assembly

will not operate properly.

Inspect center roller hydraulics for leaks.

Any Class III leak is

evident.

11

Before

Left and Right

Rear Guide

Assemblies

Check for loose or binding handle (Figure 9, Item 1):

•

Rotate handle (Figure 9, Item 1).

•

Move rear guide (Figure 9, Item 2) to its fullest

open and closed positions. Rear guide (Figure

9, Item 2) and handle (Figure 9, Item 1) should

move freely

•

Inspect rear guide assembly for cracks, bends,

or broken welds.

Handle is missing or

inoperative. Rear guide

assembly will not operate.

TM 5-3990-263-13&P

0035

0035-7

Back to Top