TM-5-3990-263-13-P - Page 328 of 728

Table

1.

Operator Preventive Maintenance Checks and Services - Continued

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

1

2

3

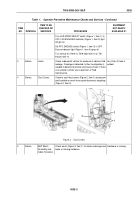

Figure 6.

Control Valve.

Inspect air cylinder (Figure 6, Item 2) and guard (Figure

6, Item 3) for damaged or missing hardware.

9

Before

Left and Right

Front Pin Locks

Check locking mechanism (Figure 7, Item 1) for

damaged or missing parts.

Front pin lock is damaged

or has missing parts.

1

2

2

3

3

1

Figure 7.

Front Pin Locks.

Check front pin lock wear pad (Figure 7, Item 2) for

excessive wear. Notify Field maintenance to turn over

wear pad (Figure 7, Item 2) if it is worn to within 1/16 inch

(1.59 mm) of screw heads, or if top edge is worn down

to 1/16 inch (1.59 mm) of metal contact. If bottom edge

has already been worn down, notify Field maintenance

to replace wear pad (Figure 7, Item 2).

Pull locking handle (Figure 7, Item 3) to see if assembly

disengages.

Front pin lock does not

engage

TM 5-3990-263-13&P

0035

0035-6

Back to Top