TM-9-2320-272-23-4 - Page 1085 of 1393

DISASSEMBLY - Continued

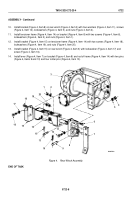

6.

Remove cotter pin (Figure 2, Item 1) and pin (Figure 2, Item 8) from tensioner frame (Figure 2, Item 2). Discard

cotter pin.

7.

Remove grease fitting (Figure 2, Item 7) from pin (Figure 2, Item 8).

8.

Remove sheave (Figure 2, Item 5), two thrust washers (Figure 2, Item 3), and packings with retainers

(Figure

2,

Item

4) from tensioner frame (Figure 2, Item 2). Discard packings with retainers.

9.

Remove bearing (Figure 2, Item 6) from sheave (Figure 2, Item 5).

10.

Remove cotter pin (Figure 2, Item 9) and pin (Figure 2, Item 16) from tensioner frame (Figure 2, Item 2). Discard

cotter pin.

11.

Remove grease fitting (Figure 2, Item 15) from pin (Figure 2, Item 16).

12.

Remove sheave (Figure 2, Item 13), two thrust washers (Figure 2, Item 11), and packings with retainers

(Figure

2,

Item

12) from frame (Figure 2, Item 2). Discard packings with retainers.

13.

Remove bearing (Figure 2, Item 14) from sheave (Figure 2, Item 13).

14.

Remove frame (Figure 2, Item 10) from tensioner frame (Figure 2, Item 2).

NOTE

Parts for both sheaves are inspected the same way.

15.

Clean and inspect thrust washers (Figure 2, Items 3 and 11) for cracks or wear. Measure thickness with a

micrometer and discard thrust washers if thickness is less than 0.055 in. (1.40 mm) or if cracked.

16.

Clean and inspect bearings (Figure 2, Items 6 and 14) for chips, cracks, scoring, or damaged cage. Discard if

chipped, cracked, scored, or cage is damaged.

17.

Clean and inspect pins (Figure 2, Item 8) and (Figure 2, Item 16) for cracks or wear. Measure with a micrometer

and discard if outer diameter is less than 1.245 in. (31.63 mm) or if cracked.

NOTE

Refer to TM 9-237 for welding and straightening techniques.

18.

Inspect sheave frame (Figure 2, Item 10) for bends and cracks. Repair minor bends or cracks.

19.

Clean and inspect tensioner frame (Figure 2, Item 2) for bends, cracks, and broken welds. Repair minor bends,

cracks, and broken welds. Replace if not repairable.

TM 9-2320-272-23-4

0722

0722-4

Back to Top