TM-9-2320-272-24-3 - Page 26 of 799

TM 9-2320-272-24-3

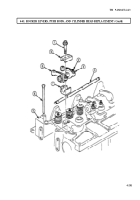

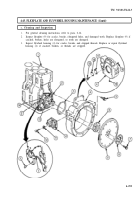

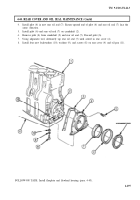

4-42. VIBRATION DAMPER MAINTENANCE

THIS TASK COVERS:

a. Removal

b. Inspection

c. Installation

INITIAL SETUP:

APPLICABLE MODELS

M939A2

SPECIAL TOOLS

REFERENCES (TM)

Engine barring tool (Appendix E, Item 43)

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 144)

MATERIALS/PARTS

O-ring (Appendix D, Item 444)

PERSONNEL REQUIRED

Two

TM 9-2320-272-10

TM 9-2320-272-24P

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-272-10).

Engine drivebelt removed (para. 3-71).

Fan and fan shroud removed (para. 3-64).

NOTE

Assistant will help with this procedure.

a. Removal

1.

Remove plug (4) and O-ring (3) from flywheel housing (2). Discard O-ring (3).

2.

Using engine barring tool, prevent crankshaft (1) from turning.

3.

Remove four screws (6) and vibration damper (5) from crankshaft (1).

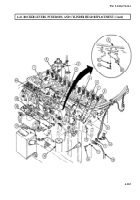

b. Inspection

1.

Inspect vibration damper (5) for bends, breaks, and damaged pulley grooves. Replace vibration

damper (5) if bent, broken, or grooves are damaged.

2.

Inspect vibration damper alignment marks (8). Replace vibration damper (5) if alignment

marks (8) are 0.063 in. (1.60 mm) out of alignment.

3.

Inspect rubber member (7) for wear and damage. Replace vibration damper (5) if damaged or worn

more than 0.125 in. (3.18 mm) deeper than face of vibration damper (5).

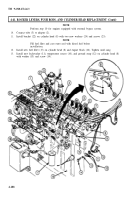

c. Installation

1.

Using engine barring tool, prevent crankshaft (1) from turning.

2.

Install vibration damper (5) on crankshaft (1) with four screws (6). Tighten screws (6) 150 lb-ft

(203 N·m).

3.

Install new O-ring (3) and plug (4) in flywheel housing (2).

4-290

Back to Top