TM-9-2320-272-24-3 - Page 28 of 799

TM 9-2320-272-24-3

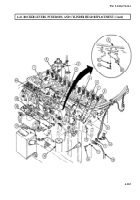

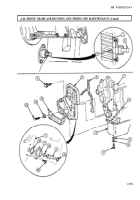

4-43. FLEXPLATE AND FLYWHEEL HOUSING MAINTENANCE

THIS TASK COVERS:

a. Removal

d. Assembly

b. Disassembly

e. Installation

c. Cleaning and Inspection

INITIAL SETUP:

APPLICABLE MODELS

M939A2

PERSONNEL REQUIRED

Two

SPECIAL TOOLS

REFERENCES (TM)

Engine barring tool (Appendix E, Item 43)

TOOLS

General mechanic’s tool kit (Appendix E, Item 1)

Torque wrench (Appendix E, Item 144)

MATERIALS/PARTS

Seal (Appendix D, Item 602)

Gasket (Appendix D, Item 189)

Antiseize tape (Appendix C, Item 72)

Gasket sealant (Appendix C, Item 30)

Lubricating oil (Appendix C, Item 50)

TM 9-2320-272-24P

EQUIPMENT CONDITION

Transmission (out-of-vehicle) removed (para. 4-72).

CAUTION

Do not use timing pin to prevent engine from turning. Doing so

may cause damage to timing pin.

NOTE

Assistant will help with this procedure.

a. Removal

1.

Using engine barring tool, prevent crankshaft (13) from turning.

2.

Remove eight screws (7), clamping ring (8), flexplate (9), and crankshaft adapter (6) from

crankshaft (13).

3.

Remove twelve screws (5), flywheel housing (4), and seal (3) from rear cover (14). Discard seal (3).

NOTE

Perform step 4 if dowel pins are damaged.

4.

Remove two dowel pins (2) from engine block (1).

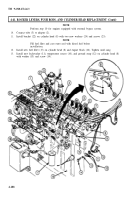

b. Disassembly

1.

Remove two pipe plugs (18) from flywheel housing (4).

2.

Remove two screws (15), cover plate (16), and gasket (17) from flywheel housing (4). Discard

gasket (17).

NOTE

Tag mounting brackets for installation. One on each side of

flywheel housing. One side shown.

3.

Remove eight screws (12), washers (11), and two mounting brackets (10) from flywheel housing (4).

4-292

Back to Top