TM-9-2320-273-34 - Page 239 of 801

TM 9-2320-273-34

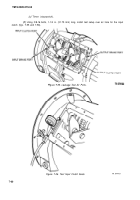

b. Input Clutch and Brake Seal Test.

(1) Put air

pressure through test line until indication on test gage is

90-100

psi

(620-690

kPa).

(2)

After 10 seconds, close shutoff valve and start the timer.

(3)

If the pressure decrease is not more than 5 psi (35 kpa) in 11 seconds, the inPut clutch seals

are good. Repeat test three times.

If satisfactory, remove air pressure fitting from input clutch port and

continue with test.

(4)

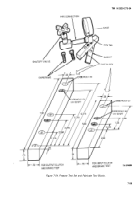

Install test setup over air hole for input brake (fig. 7-55).

(5)

Put air pressure through test line until the indication on the test gage is 90-100 psi (620-

690 kPa).

(6) After 10 seconds, close shutoff valve and start the timer, If the pressure decrease is not

more than 5 psi (35 kPa) in 3 seconds, the input brake seals are good. Repeat test three times. If satis-

factory, remove test setup and continue with test.

c. Output Clutch and Brake Seal Test.

(7) Install test setup (with long test b

7-57).

ock over air hole for the output clutch (fig. 7-55 and

Figure 7-57. Test Output Clutch Seals.

(2)

Put air pressure through test line until the indication on test gage is 90-100 psi (620-

690 kPa).

(3) After 10 seconds, close shutoff valve and start the timer.

7-61

Back to Top