TM-9-2320-273-34 - Page 608 of 801

TM9-2320-273-34

16-3. Installation.

a.

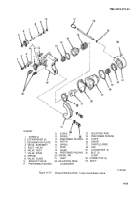

Slide lower steering column universal (6, fig. 16-1 ) over the worn gear shaft on the steering gear

and aline steering gear mounting holes.

b.

Install the four mounting bolts (14), washers (17), (15) and nuts (16). Torque nuts to 260-280

Ib-ft (353-380 N.m).

Install bolt (7), Iockwasher (3), and nut (2) in lower steering column universal (6)

35 lb-ft (47 N.m).

d.

Drive a wedge in the slot on the pitman arm to open up slightly, making sure that

shaft alinement mark (9) and pitman arm alinement mark (10) are properly positioned. Tap

(11) onto the sector shaft (13) using a soft headed hammer.

Torque to

the sector

pitman arm

Install the pitman arm clamp retaining nut (8) and bolt (12). Torque to 380-420 Ib-ft

(515-569 N.m).

f.

Fill and bleed the hydraulic system. (Refer to TM 9-2320-273 -20.)

9.

Install the left front fender. (Refer to TM 9-2320-273 -20.)

16-4. Adjustment.

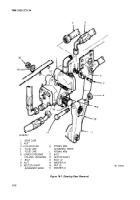

The purpose of this procedure is to set the poppet adjusting screws (fig. 16-2) so that

the poppet contacts the screw just before full lock position is attained. Then at full lock (when steering

against axle stops) the poppet should be fully tripped and pressure shown by a gage in discharge line

should be between 400 and 900 psi at 4.5 gallons per minute. Adjust as follows:

16-3

c.

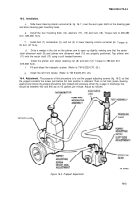

Figure 16-2. Proppett Adjustment

TA 074403

Back to Top