TM-9-2320-273-34 - Page 623 of 801

TM9-2320-273-34

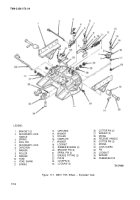

Section V. ON-VEHICLE STEERING GEAR REPAIRS

16-20. Description.

Since removal of the steering gear from the vehicle is difficult and time consuming, it’s

often easier to perform the necessary repairs and adjustments on the vehicle. After cleaning, if the steering

gear is visibly leaking fluid or there is a high rate of internal leakage, a seal has probably failed.

16-21. Output Shaft Seal Replacement

a.

Preparation.

(1)

Raise vehicle’s front end

(2) Remove left front wheel

b. Procedures.

(1)

Remove the pitman arm

(Figure 16-8).

and secure with jack stands positioned under front axle.

for accessability to steering gear.

clamp retaining nut (9) and bolt (8).

(2)

Put alinement marks on the end of the sector shaft (11) and the pitman arm (10) to facili-

tate reassembly. Using a pitman arm puller, remove the pitman arm (10) from the steering gear sector

shaft (1 1) to gain access to the output shaft seal area.

(3)

Remove the dust seal (7) and clean the output shaft. Clean the exposed shaft with

emery paper.

(4)

Place a container under the steering gear, to capture hydraulic fluid lost, when trunnion

cover and shaft seal package are removed.

(5)

Remove the four trunnion cover’s cap screws (6) holding the trunnion cover (5) on the

steering gear. Remove trunnion cover (5) and the shaft seal package (2, 3, & 4).

(6) place the trunnion cover (5) on a bench in order to install a new seal package. Begin with

the teflon back-up washer (4), followed by the two-piece output shaft seal (3).

NOTE

The words “oil side” must face inward

toward the gear.

(7)

Grease the new O-ring seal (2) and install it in the cover groove.

(8)

T

O

avoid damaging the new seals, tape over the serrations on the output shaft. Replace

the trunnion cover (5) and install a new dust seal (7). Install the trunnion covers cap screws (6) and torque

them 15-22 Ib-ft. (20-30 N-m). Remove the tape over the serrations on the output shaft.

(9) 'Drive a wedge in the slot on the pitman arm to open up slightly, making sure the sector

shaft alinement mark (12) and the pitman arm alinement mark (13) are properly positioned. Tap pitman

arm (10) onto the sector shaft (11 ) using a soft headed hammer. Install the pitman arm clamp retaining

nut (9) and bolt (8). Torque to 380-420 Ib-ft. (515-569 N-m).

16-18

Change 1

Back to Top