TM-9-2320-280-34 - Page 354 of 1258

TM 9-2320-280-34

6-4.

200 AMPERE ALTERNATOR (A0013036AA) TESTING AND REPAIR (Cont ’d)

)

19.

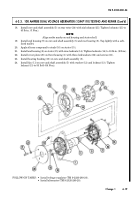

Perform rotor coil ground test as follows:

Set ohmmeter to X10K scale.

Connect one probe to a bare metal surface on the rotor shaft.

Insert the second test lead in the housing and contact probe to each of the two slip rings.

If a

LOW resistance is noted (less than 50,000 ohms) then the rotor coil is grounded and the

alternator must be replaced.

20.

Perform rotor coil resistance test as follows:

Set ohmmeter to X1 scale and insert the two probes in brush holder opening in the housing.

Connect a probe to each of the two slip rings.

Correct resistance is 5.0-6.0 ohms.

If resistance

falls outside values shown, then the rotor coil is defective and alternator must be replaced.

NOTE

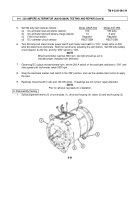

•

The stator is the most difficult component to test.

If all

components are acceptable, then the stator should be replaced, as

it is most likely to be misdiagnosed as being serviceable.

•

Perform steps 21 through 28 when disassembling the complete

alternator.

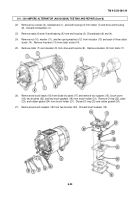

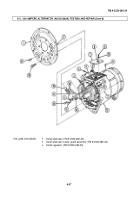

21.

Remove locknut (1), woodruff key (2), and fan (3) from rotor shaft (4).

Discard woodruff key (2) and

locknut (1).

6-29

Back to Top