TM-9-2320-361-20 - Page 315 of 1207

TM 9-2320-361-20

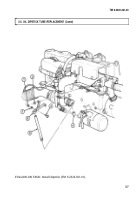

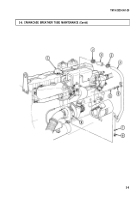

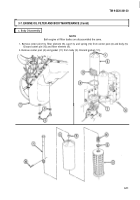

3-7. ENGINE OIL FILTER AND BODY MAINTENANCE (Contd)

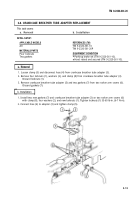

d. Cleaning and Inspection

WARNIN G

Drycleaning solvent is flammable and will not be used near open flame. Use only

in well-ventilated places. Failure to do so may result in injury to personnel.

Compressed air source will not exceed 30 psi (207 kPa). When cleaning with

compressed air, eyeshields must be worn. Failure to wear eyeshields may result

in injury to personnel.

1. Clean center post (1) and body (2) with drycleaning solvent and dry with compressed air.

2. Inspect body (2) for cracks. Replace body (2) if cracked.

3. Inspect center post (1) for stripped threads. Replace center post (1) if threads are stripped.

4. Inspect filter housing (4) for cracks, nicks, and stripped threads. Notify your supervisor if filter

housing (4) is cracked, nicked, or threads are stripped.

5. Inspect cup (8) for cracks and grooves. Replace cup (8) if cracked or grooved.

6. Inspect spring (7) for cracks and breaks. Replace spring (7) if cracked or broken.

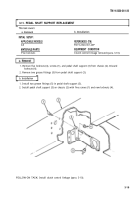

e. Body Assembly

NOTE

Both engine oil filter bodies are assembled the same.

1. Place new gasket (6) on center post (1) and install center post (1) on filter body (2).

2. Install spring (7), cup (8), new filter element (9), and new cotter pin (5) on center post (1) and

body (2).

f. Oil Filter Installation

NOTE

Both engine oil filter bodies are installed the same.

1. Coat new gasket (4) with light film of engine oil.

2. Install new gasket (4) and body (2) on filter housing (3). Tighten center post (1)60 lb-ft (81 N·m).

FOLLOW-ON TASKS:

Fill to proper oil level (LO 9-2320-209-12-1).

Start engine (TM 9-2320-361-10) and check for leaks.

3-12

Back to Top