TM-9-2330-202-13-P - Page 154 of 552

Table

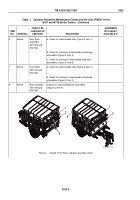

1.

Field Preventive Maintenance Checks and Services (PMCS) for

the M101 and M116 Series Trailers - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

10

Annual

Hydraulic Brake

System

a. Inspect wheel cylinders for leaks.

Any leaks are found.

b. Check hydraulic brake actuator assembly for damage

and security of mounting.

c. Check hydraulic brake lines and fittings for dents,

cracks, loose connections, and leaks.

Any leaks are found.

11

Annual

Wheel

Assemblies

a. Inspect tires for wear and damage. Check tread depth

TM 9-2610-200-14.

b. Check tire pressure when tires are cool (WP

0002).

NOTE

•

Turn lug nuts clockwise to tighten and

counterclockwise to loosen.

•

If vehicle is equipped with runflat tires,

torque lug nuts between 112 – 138 lb-ft

(152 – 187 N•m). For other tire

configurations, torque lug nuts between

110 – 120 Ib-ft (149 – 163 N•m).

c. Check wheels for damage and lug nuts for tightness

and presence.

12

Annual

Wheel Bearings

Replace wheel bearings

(WP

0054)

or

(WP

0055).

13

Annual

Frame

Inspect frame for cracks, bent members, and

broken welds.

14

Annual

Suspension

Assemblies

a. Inspect shackles, bushings, shackle pins, and spring

eyes for damage or broken parts.

b. Inspect spring assemblies for cracked or

shifted leaves.

c. Inspect spring hangers for obvious damage.

d. Inspect shock absorbers for leaking, damage, and

security of mounting.

15

Annual

Data Plates

Make sure data plates can be read and are firmly

attached. Replace if damaged or disfigured (WP

0073).

16

Annual

Road Test

Perform road test. Give special attention to items that

were repaired or adjusted. Be alert for unusual or

excessive noises that may indicate damage, looseness,

defects, or deficient lubrication in attachments or wheels.

END OF TASK

END OF WORK PACKAGE

TM 9-2330-202-13&P

0033

0033-2

Back to Top