TM-9-2330-238-14

CHASSIS, SEMITRAILER: 6-TON, 4-WHEEL M295A1; SEMITRAILER, VAN: EXPANSIBLE, 6-TON, 4-WHEEL M313; SEMITRAILER, VAN: SHOP, FOLDING SIDES, 6-TON, 4-WHEEL M447 AND M447C; SEMITRAILER, VAN: REPAIR PARTS, SHOP EQUIPMENT, 6-TON, 4-WHEEL M749; SEMITRAILER, VAN: REPAIR PARTS STORAGE, 6-TON, 4-WHEEL M750

TECHNICAL MANUAL; OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

JULY 1992

TM-9-2330-238-14 - Page 338 of 462

TM

9-2330-238-14

5-13.

LANDING

GEAR

LEG ASSEMBLY

REPAIR

(EARLY MODEL)

(Con’t).

1.

2.

3.

4.

5.

6.

7.

8.

WARNING

Dry cleaning

solvent,

P-D-680,

is toxic and flammable.

Always wear protective

goggles

and gloves,

and use only in a well-ventilated

area.

Avoid contact

with skin, eyes,

and

clothes,

and DO NOT breathe

vapors.

DO NOT use near open flame

or excessive

heat.

The

solvent’s

flash

point

is 100°F-138°F

(38°C-59°C).

If you

become

dizzy

while

using cleaning

solvent,

Immediately

get fresh air and medical

help. if solvent

contacts

eyes,

Immediately

wash

your

eyes

and get medical

aid.

Clean

all parts with

dry cleaning

solvent

and dry thoroughly.

Inspect

screw

leg assembly

for damage,

wear, or corrosion.

Inspect

roller bearings

for pits, corrosion,

or wear and replace

if unserviceable

(Refer to TM 9-214

for care and

maintenance

of bearings).

Inspect

bevel

gears

for cracked,

chipped,

or worn

gear teeth.

Inspect

drive

shaft and intermediate

drive

shaft for cracks,

bends,

or breaks.

Check

contact

surface

of leveling

gib on lower

leg assembly

is smooth.

If not, remove

burrs with fine file and

abrasive.

Inspect

all mounting

hardware

for cracks,

bends,

or stripped

threads.

Replace

all defective

parts

as necessary.

1.

2.

3.

4.

5.

6.

7.

8.

5-36

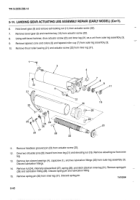

Install two

sleeve

bearings

(10) and new lubrication

fittings

(33) in upper

leg assembly

(34).

Position

screw leg assembly

(21) in lower leg assembly

(26) and install nut retainer (20). Secure nut retainer with

two new spring

pins

(25).

Install

thrust washer

bearing

(19) and ratchet

wheel

(18) on screw

leg assembly

(21).

NOTE

Control

cam is stamped

with the letter T on one side to indicate

the top. Ensure control

cam is assembled

accordingly.

Install

thrust roller

bearing

(15) and control

cam

(16) in clutch

case

(14) and secure

with retaining

ring (17).

Install

clutch

case

(14) on screw

leg assembly

(21).

Install

lower

leg assembly

(26) and screw

leg assembly

(21) in upper

lieg assembly

(34), taking

care

not to

damage

threads

on screw

leg assembly.

Install sleeve

bearing

(13), tapered

roller cup (9), tapered

cone and rollers (8), machine

key (5), and bevel gear

(7) on screw

lieg assembly

(21) and secure

with new self-locking

nut (4).

Tighten

self-locking

nut (4) just enough

to allow

screw

leg assembly

(21) to turn freely with a minimum

of end

play.

Back to Top