TM-9-2330-238-14

CHASSIS, SEMITRAILER: 6-TON, 4-WHEEL M295A1; SEMITRAILER, VAN: EXPANSIBLE, 6-TON, 4-WHEEL M313; SEMITRAILER, VAN: SHOP, FOLDING SIDES, 6-TON, 4-WHEEL M447 AND M447C; SEMITRAILER, VAN: REPAIR PARTS, SHOP EQUIPMENT, 6-TON, 4-WHEEL M749; SEMITRAILER, VAN: REPAIR PARTS STORAGE, 6-TON, 4-WHEEL M750

TECHNICAL MANUAL; OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

JULY 1992

TM-9-2330-238-14 - Page 330 of 462

TM

9-2330-238-14

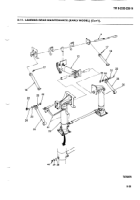

5-11.

LANDING

GEAR

MAINTENANCE

(EARLY MODEL)

(Con’t).

38.

Remove

plug

retaining

clips

(39), gib retaining

plugs

(40), and gibs

(38) from each support

leg assembly

(26).

39.

Aline

holes

in ends

of cross

shaft

(8) with holes

in upper

braces

(18) and install

two new

spring

pins

(17).

40.

Position

support

leg assemblies

(26) so upper

and lower

braces

(18 and 25) are in line.

NOTE

Center

of pin In brace hinge must be a minimum

of ~

In. (3.18

mm) below

normal center

Iine of brace

with

surface

of lower

brace

at contact

point. If necessary,

hand

file or

machine

upper

brace

surface

and/or

surface

of lower

brace.

41.

Install

pins

(24) at hinge

point

of each brace

and secure

each pin with two bearing

sleeves

(23) and two new

retaining

rings

(22).

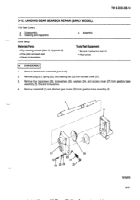

1.

Turn handcrank

(41) until

distance

from

ends

of inner and

outer

legs

of actuating

leg assembly

(12)

is

7 in.

(15.78 cm).

2.

Loosen

four capscrews

(56) and two nuts (58).

3.

If roller (64) is too high, turn two capscrews

(59) counterclockwise

until roller can be forced

down

on flat surface

(67) of inner leg of actuating

leg assembly

(12).

4.

Turn two

capscrews

(59) clockwise

until snug and tighten

two nuts (58). Tighten

four capscrews

(56).

5.

Turn handcrank

(41) until roller

(64) just makes

contact

with

inner leg of actuating

leg assembly

(12).

5-28

Back to Top