TM-9-2330-238-14

CHASSIS, SEMITRAILER: 6-TON, 4-WHEEL M295A1; SEMITRAILER, VAN: EXPANSIBLE, 6-TON, 4-WHEEL M313; SEMITRAILER, VAN: SHOP, FOLDING SIDES, 6-TON, 4-WHEEL M447 AND M447C; SEMITRAILER, VAN: REPAIR PARTS, SHOP EQUIPMENT, 6-TON, 4-WHEEL M749; SEMITRAILER, VAN: REPAIR PARTS STORAGE, 6-TON, 4-WHEEL M750

TECHNICAL MANUAL; OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

JULY 1992

TM-9-2330-238-14 - Page 328 of 462

TM

9-2330-238-14

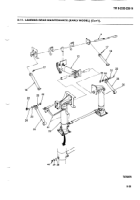

5-11.

LANDING

GEAR

MAINTENANCE

(EARLY MODEL)

(Con’t).

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

Turn drive shaft (44) of actuating

leg assembly (12)

by hand until distance

from ends of inner and outer actuating

legs

is 5 in. (12,70 cm).

Position

actuating

leg assembly

(12) and drive shaft (44) in frame with forward

end against

crossmember.

Aline

mounting

holes

and install,

hand tight,

two capscrews

(13), new Iockwashers

(14), and nuts (15).

Support

rear of actuating

leg assembly (12)

on blocks.

Install

cross

shaft

(8), roller

arms (5) and bearing

block

(7) as a unit in frame

holes.

Aline mounting holes in bearing

block (7)

and rear mounting

bracket

of actuating

leg assembly (12)

with holes in

crossmember.

Install,

hand tight,

two capscrews

(6), new Iockwashers

(10), and nuts (11).

Slide

semitrailer

brackets

(2) and upper braces

(18) on ends of cross

shaft (8) with flat surface

of braces,

hinge

end facing

down.

Aline holes

in two semitrailer

brackets

(2) with holes

In frame and install,

hand tight, twelve

capscrews

(1), new

Iockwashers

(3), and nuts (4).

Aline

drive

shaft (44) in actuating

leg assembly

(12) parallel

with crossmember

and tighten

two nuts (15) and

capscrews

(13) securing

forward

end of actuating

leg assembly

to crossmember.

Tighten

socket

head

setscrew

(9) until flat surface

at top

of inner leg of actuating

leg assembly

(12) is snug

against

bottom

of crossmember.

Aline

cross

shaft (8) parallel

with crossmember

and tighten

two nuts (11) and capscrews

(6) securing

bearing

block

(7) and rear mounting

bracket

of actuating

leg assembly

(12) to crossmember.

Tighten

12 nuts (4) and capscrews

(1) securing

two semitrailer

brackets

(2) to frame. Check to ensure cross shaft

(8) turns freely

after securing

each bracket.

Position

and install

left support

leg assembly

(26) with intermediate

drive shaft (16) through

hole in frame and

over end of drive

shaft (44).

Secure

support

leg assembly

(26) and support

leg bracket

(37) to frame with six capscrews

(42), two spacers

(19), new

Iockwashers

(20), and nuts (21). Ensure that weight

is relieved

from

intermediate

drive

shaft

(16)

before

securing

support

leg assembly.

Install two

lower

braces

(25) on cross

tube assembly

(36) with flat surface

of brace

hinge

ends facing

down.

Install

end of cross

tube

assembly

(36) into left support

leg assembly

(26).

Repeat steps 28 and 29 and install right support

leg assembly

(26). Ensure right end of cross tube assembly

(36)

is installed

in right support

leg assembly

before

securing

it to frame.

Aline holes in upper ends of diagonal

braces

(27) with mounting holes in support

leg assemblies

(26), Install two

capscrews

(29) and new Iockwashers

(28).

Install two capscrews

(35), new Iockwashers

(30), and nuts (31) in lower ends of diagonal

braces

(27) and cross

tube

assembly

(36).

Install

capscrew

(32), new Iockwasher

(33), and nut (34) in diagonal

braces

(27).

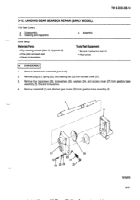

Using

handcrank

(41), turn

intermediate

drive

shaft

(16) until

holes

in shafts

on right

side

of actuating

leg

assembly

(12) are alined.

Install

capscrew

(45) and new self-locking

nut (43).

Repeat step 36 to install capscrew

(45) and new self-locking

nut (43) on left side of actuating

leg assembly

(12).

5-26

Back to Top