TM-9-2330-247-14-P - Page 114 of 320

TM 9-2330-247-14&P

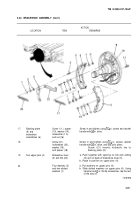

4-32.

BRAKESHOE ASSEMBLY (Con’t)

ACTION

LOCATION

ITEM

REMARKS

CAUTION

Use care in handling brakeshoe assemblies. Grease, oil, or

solvent on lining surfaces will ruin linings.

NOTE

For more information on how to clean parts, refer to

paragraph 4-20.

11.

All metal parts

Using dry cleaning solvent and brush, clean.

INSPECTION AND REPLACEMENT

NOTE

For more information on how to inspect parts, refer to

paragraph 4-21.

12.

Upper and lower

Look for spaces between coils, extended length,

springs (17 and 23)

and other signs of stretch.

13.

14.

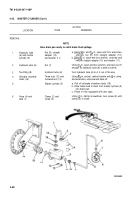

INSTALLATION

15.

Two brakeshoe

assemblies (6)

16.

Backing plate

(9)

WARNING

When brakeshoe linings are worn to within XG in. (1.6 mm) of

rivets, brakeshoes must be replaced. Failure to do so could

result in injury or death to personnel.

Brakeshoe

a. Look for glazed or loose condition,

linings

b. Using machinist rule, measure lining thickness.

Linings should not be worn to within XG In.

(1.6 mm) above rivets.

c. If glazed, loose, or worn, replace brakeshoe

assemblies.

All parts

Two upper pins

(4), two lower

pins (5), four

Iockwashers (7),

and four nuts (8)

Two brakeshoe

assemblies (6)

Look for bends, cracks, gouges, breaks, or severe

signs of wear.

a. Put in place using 1Mb in. socket, ratchet handle

with

~ in. drive, and slip-joint pliers.

b. Screw in and tighten.

Slide into position.

End with big notch seats against

adjustment screw (10).

4-60

Back to Top